Production Capacity Guarantee – Large-Scale Production

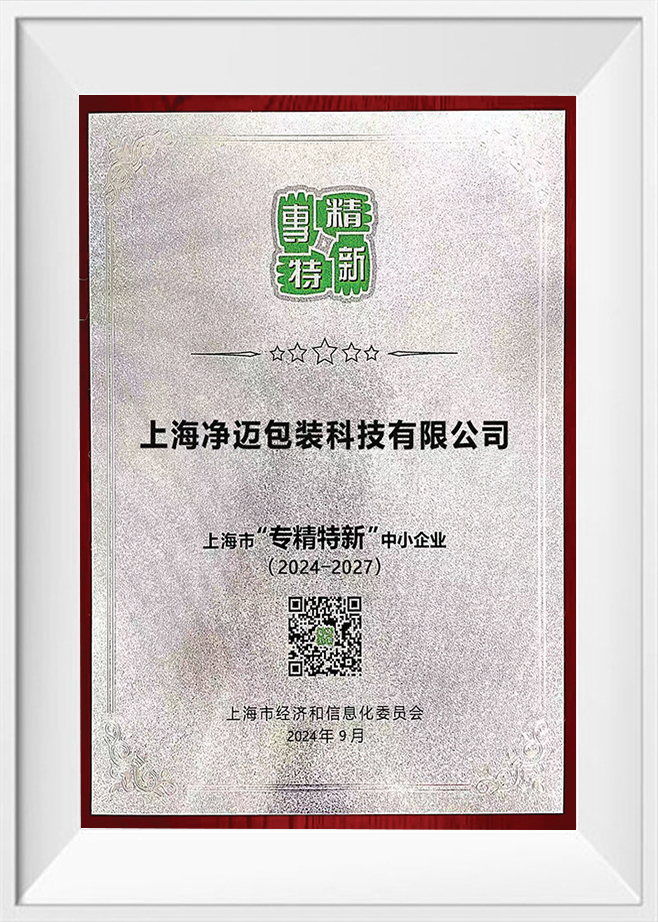

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Cake Packaging Boxes Manufacturers and OEM Cake Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

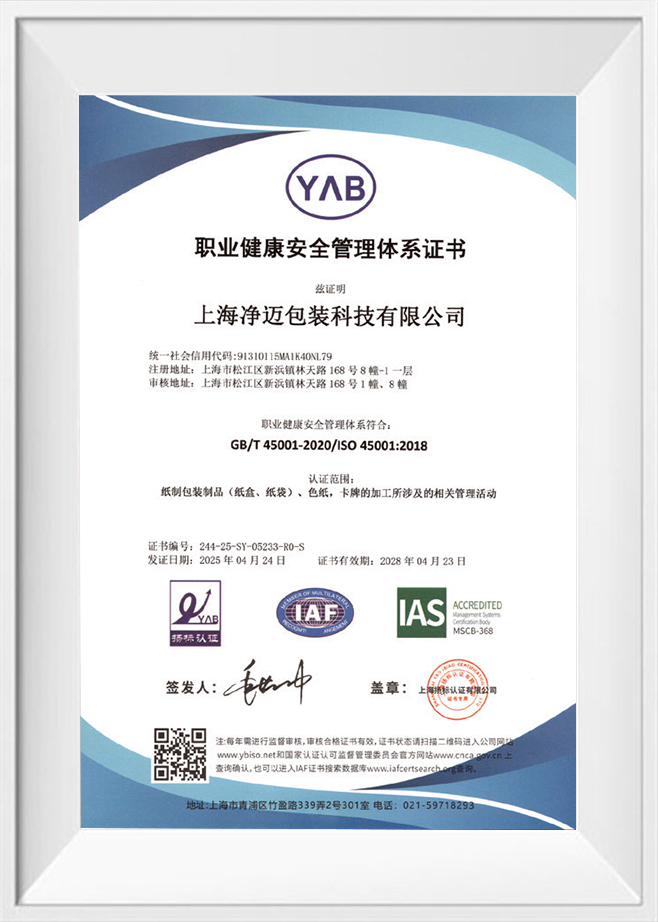

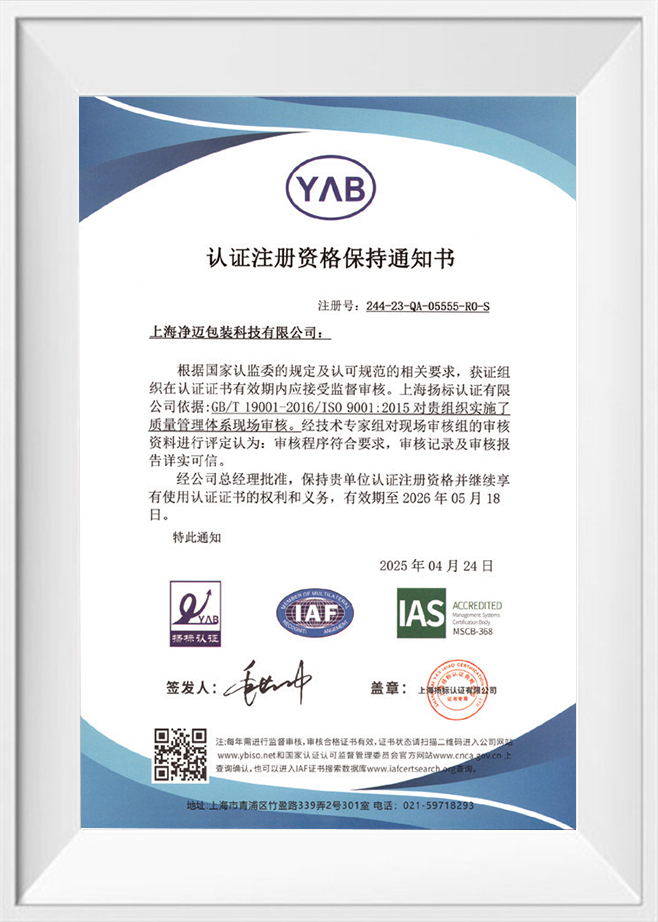

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

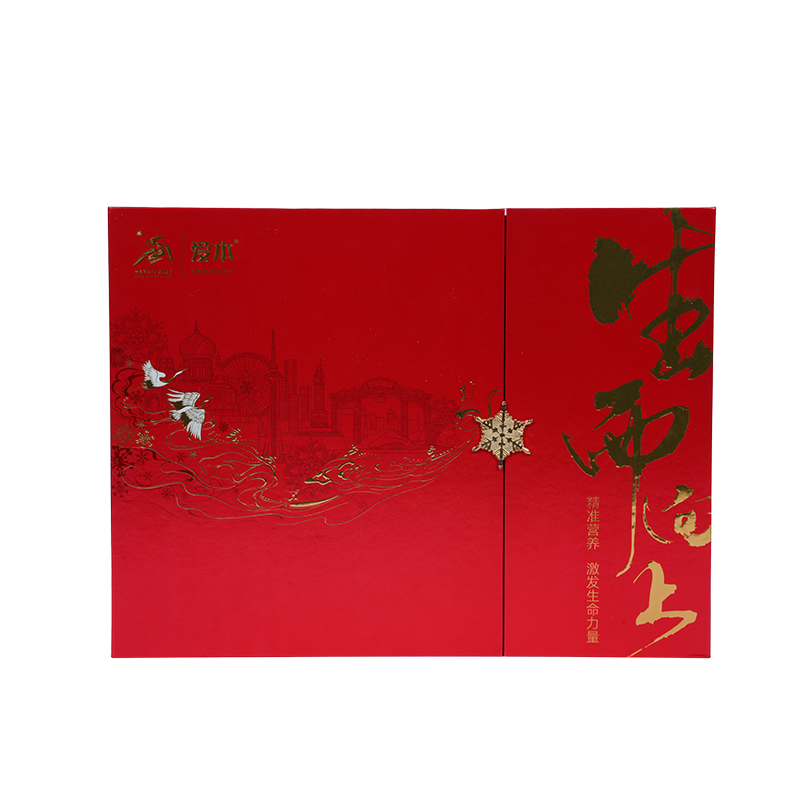

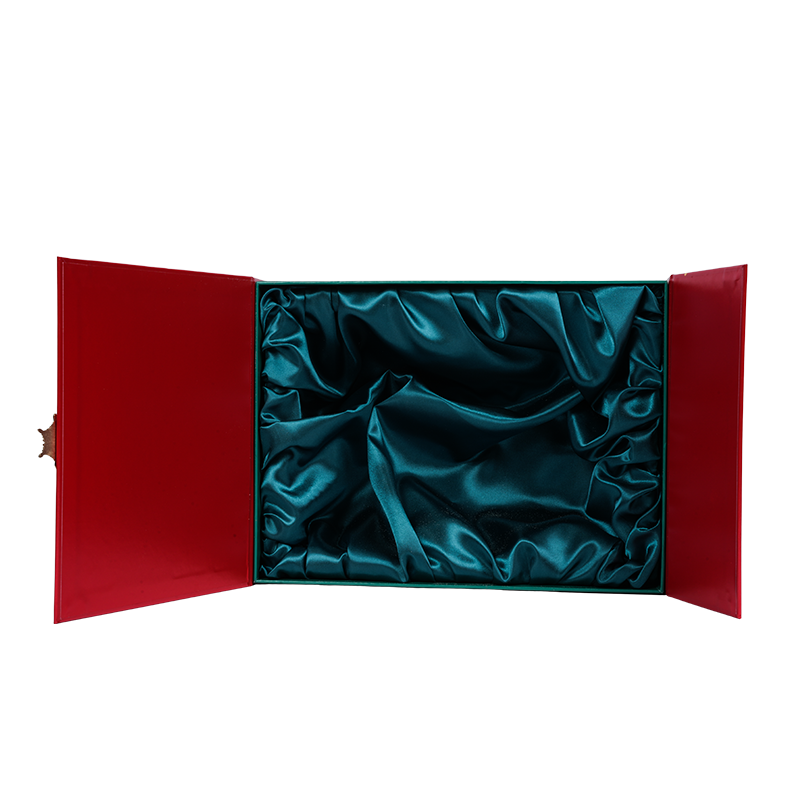

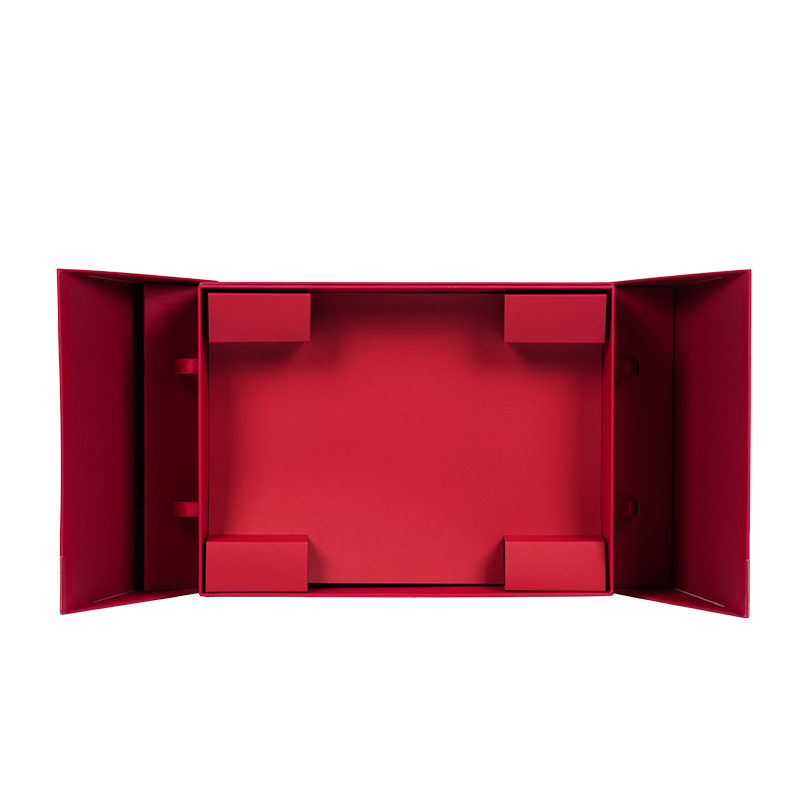

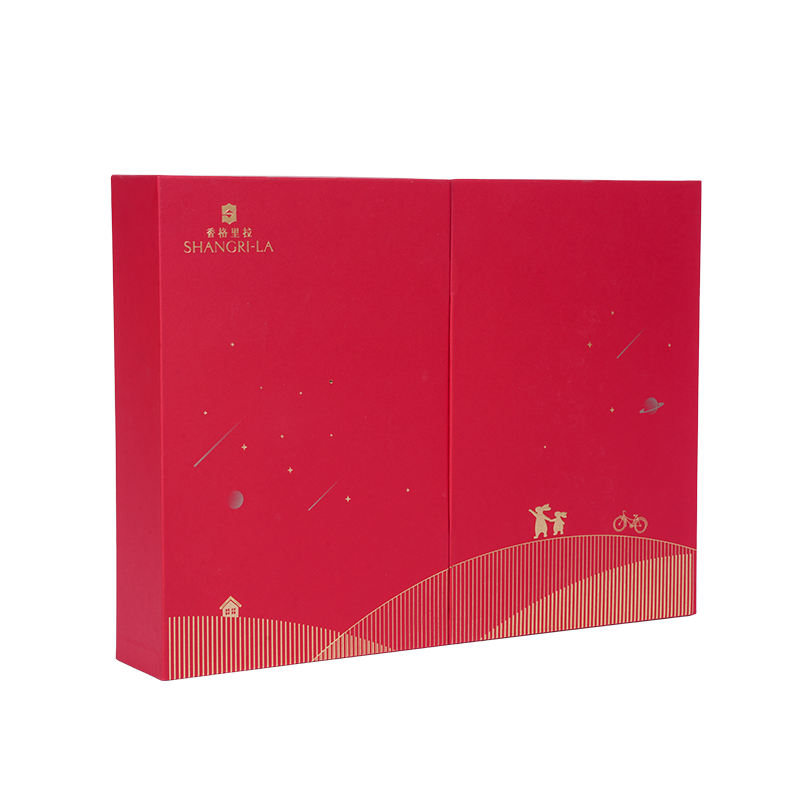

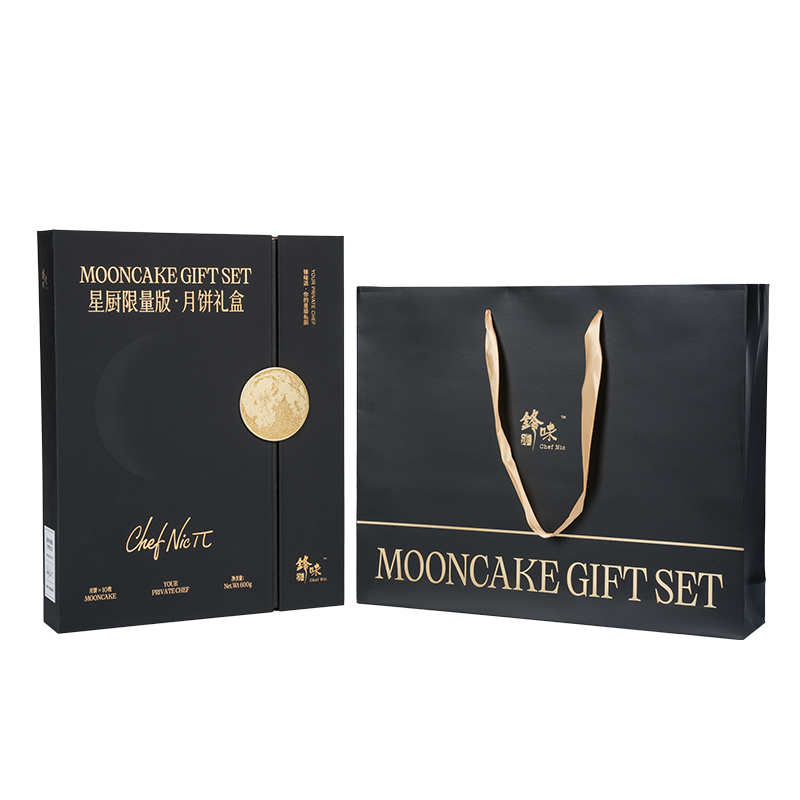

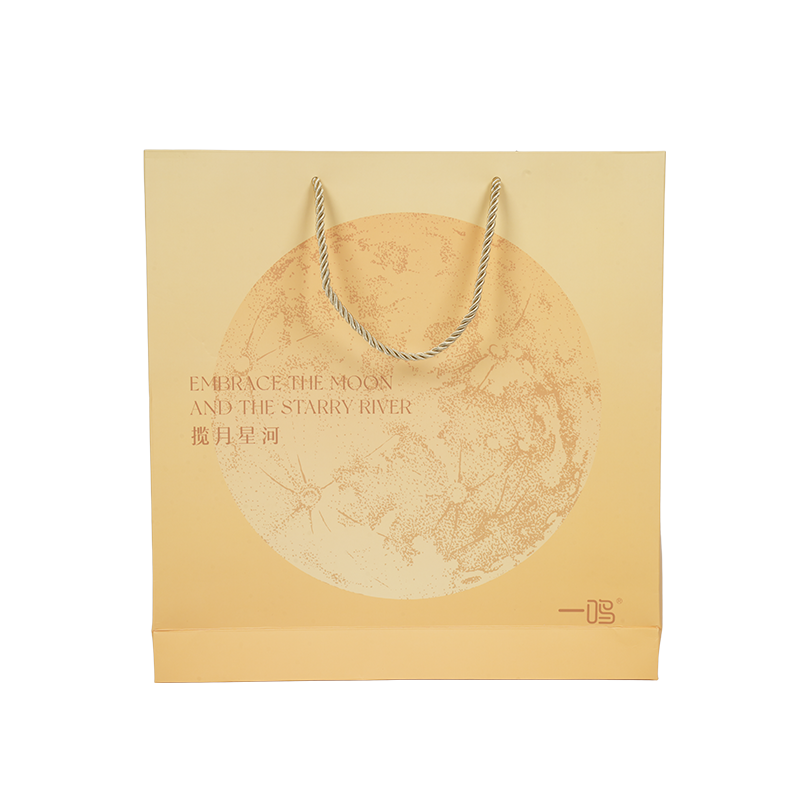

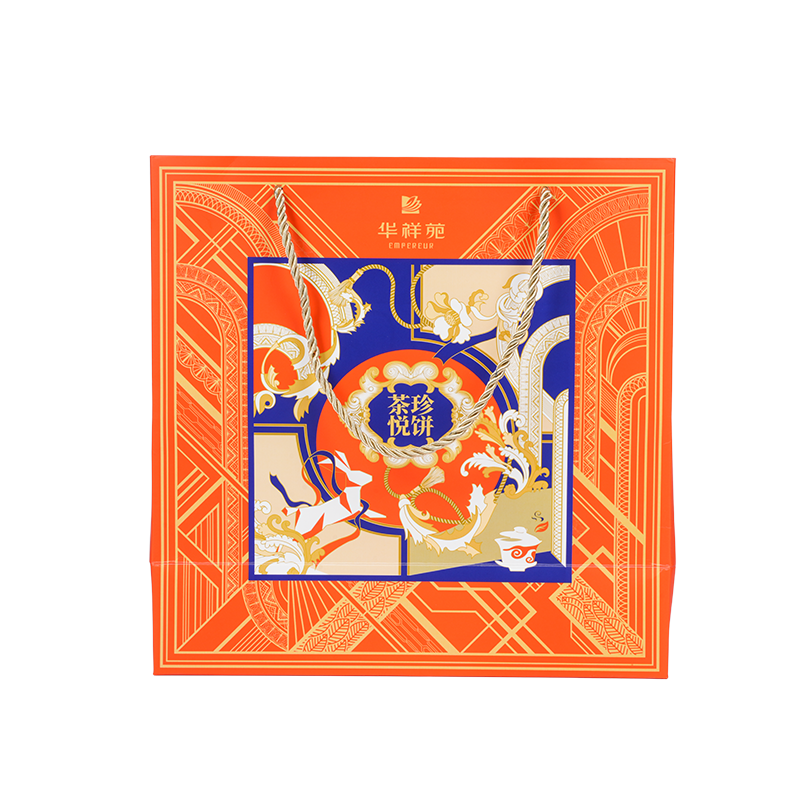

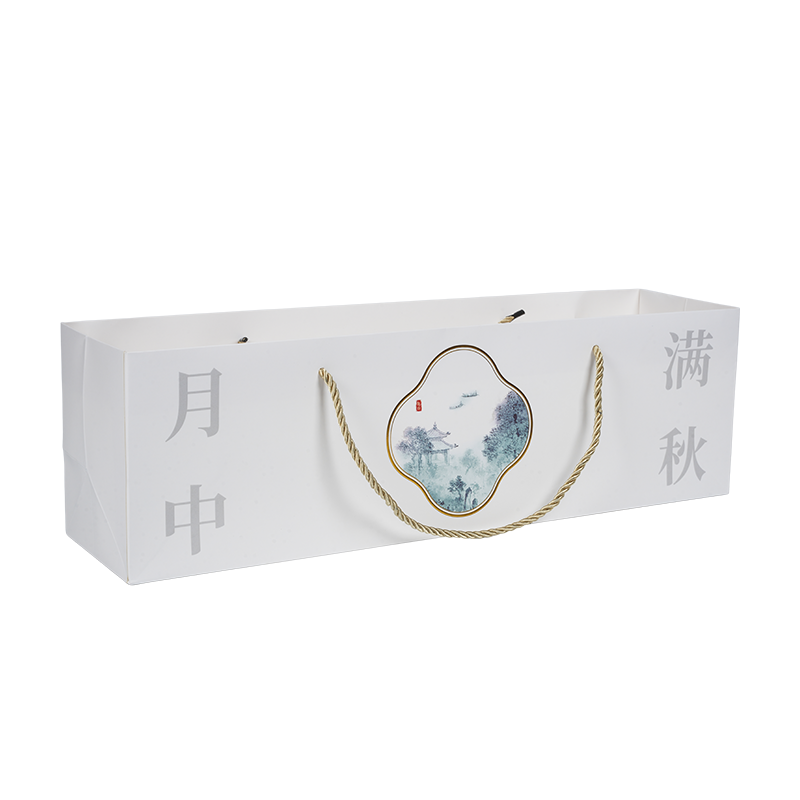

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Cake Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Cake Packaging Boxes Manufacturers

Cake packaging solves three core challenges—deformation, contamination, and temperature sensitivity—while delivering seamless performance across storage, delivery, and gifting scenarios.

1. Core Protection: Preserve Shape & Freshness

Crush-Resistant Structure: Rigid cake boxes (paperboard, PET clear boxes) with internal trays and side supports prevent shifting, collapse, or frosting damage during transport.

Hygienic & Sealed: Airtight closure blocks dust, microbes, and handling—ideal for exposed desserts like sliced cakes and mousse.

Temperature & Moisture Control: Insulated layers or ice-gel pockets slow cream melting (summer/long-haul delivery); moisture-barrier liners maintain texture.

Light Protection: Opaque boxes shield against UV, reducing color fading and oxidation for short-term freshness.

2. Scenario-Driven Design: From Delivery to Gifting

Delivery-Safe: Ergonomic handles and balanced weight distribution minimize tipping—optimized for takeout and third-party logistics.

Gift-Ready: Custom finishes (foil stamping, illustrated panels, ribbon slots) + transparent windows showcase cake aesthetics—perfect for birthdays, weddings, or corporate gifts.

Smart Storage: Freezer- and fridge-safe (food-grade certified) designs allow resealing of leftovers; single-serve portion boxes reduce waste.

Scalable Sizing: From mini cupcake sleeves to multi-tier cake boxes—fits retail display and varied order formats.

3. Compliance & Brand Value

Regulatory Ready: Pre-printed space for ingredients, allergens (e.g., eggs, nuts), expiry date, and storage instructions—meets food packaging standards.

Premium Perception: High-end gift boxes or themed designs justify premium pricing and differentiate from generic bakery offerings.

Brand Amplification: Signature colors, logo placement, and structural uniqueness (e.g. dome lids, modular layers) reinforce brand identity—luxury, playful, or health-focused.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Structural Engineering Choices That Reduce Transport Loss

In bulk cake packaging boxes, structural failure is a hidden cost driver. Beyond basic rigidity, professional buyers often evaluate load transfer paths within the box—how vertical pressure from stacking is redirected to sidewalls instead of the cake surface. This is why reinforced corners, double-wall paperboard, and integrated base trays outperform single-sheet folding designs in long-distance logistics.

From our experience supplying large-volume bakery chains, internal tray-lock systems can reduce deformation claims during delivery by a noticeable margin, especially for cream cakes and soft sponge bases. These structures also allow more aggressive pallet stacking without compromising product integrity.

Material Selection and Its Impact on Shelf-Life Stability

Moisture, Oxygen, and Grease Migration

Different cake categories place very different demands on packaging materials. High-fat cakes are sensitive to grease migration, while mousse and fruit-based desserts are more vulnerable to moisture imbalance. Selecting coated paperboard, PET clear boxes, or laminated liners is less about appearance and more about controlling micro-environmental exchange.

| Material Type | Moisture Resistance | Visual Display | Typical Use Case |

|---|---|---|---|

| Coated Paperboard | Medium–High | Low | Daily retail, delivery |

| PET Clear Box | High | Very High | Gifting, premium display |

| Laminated Board | High | Medium | Cold-chain transport |

Temperature Control Features for Extended Delivery Windows

For bulk buyers operating in warm climates or using third-party delivery platforms, temperature volatility is often more damaging than physical shock. Advanced cake packaging boxes now integrate insulated air layers, reflective liners, or ice-gel compartments to slow thermal transfer without adding excessive weight.

- Double-wall constructions create passive insulation using trapped air.

- Removable gel-pack slots allow seasonal temperature management without redesigning the box.

- Moisture-resistant liners prevent condensation from degrading cake texture.

We often recommend these features for premium cakes with buttercream or fresh fruit, where even short exposure to heat can impact presentation and perceived quality.

Regulatory Labeling as a Functional Design Element

Compliance labeling is frequently treated as an afterthought, yet for high-volume buyers it directly affects operational efficiency. Cake packaging boxes designed with pre-allocated label zones reduce packing errors and speed up order fulfillment, especially when allergen or expiry information varies by batch.

From a brand perspective, integrating these zones into the structural layout—rather than overlaying stickers—maintains a clean aesthetic while still meeting food packaging standards. This balance between regulation and presentation is often what separates commodity packaging from premium systems.