Production Capacity Guarantee – Large-Scale Production

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Candy Packaging Boxes Manufacturers and OEM Candy Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

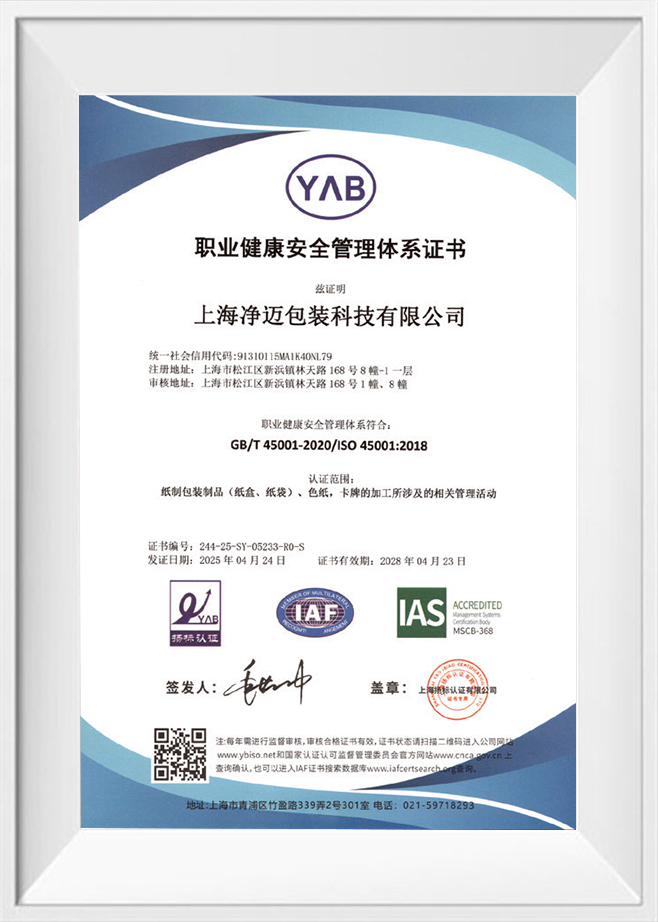

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Candy Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Candy Packaging Boxes Manufacturers

1. Core Protection: Preserving Candy Quality

Moisture and Stickiness Prevention

Packaging boxes paired with food-grade liners such as greaseproof paper or aluminum foil bags help isolate ambient moisture, preventing candies from softening or sticking together. This is especially suitable for moisture-sensitive products like chocolates and hard candies.

Compression and Damage Prevention

Rigid packaging boxes made of paperboard or tin provide buffering against pressure during transportation and stacking, protecting the shape and structure of candies such as brittle candy or filled candy from cracking.

Light Protection for Freshness

Some packaging boxes use light-blocking materials to prevent direct sunlight from causing fading or flavor loss, helping extend the product’s shelf life.

Hygiene and Dust Prevention

Sealed packaging helps keep out dust and bacteria, maintaining cleanliness. This is particularly suitable for long-term storage or bulk display.

2. Scenario Adaptation: Meeting Diverse Usage Needs

More Presentable for Gifting

Gift boxes can be customized with hot stamping, cartoon graphics, and festive elements. With integrated handles, they fit occasions such as birthdays, holidays, and wedding favors, enhancing the sense of ceremony.

Convenient Storage and Access

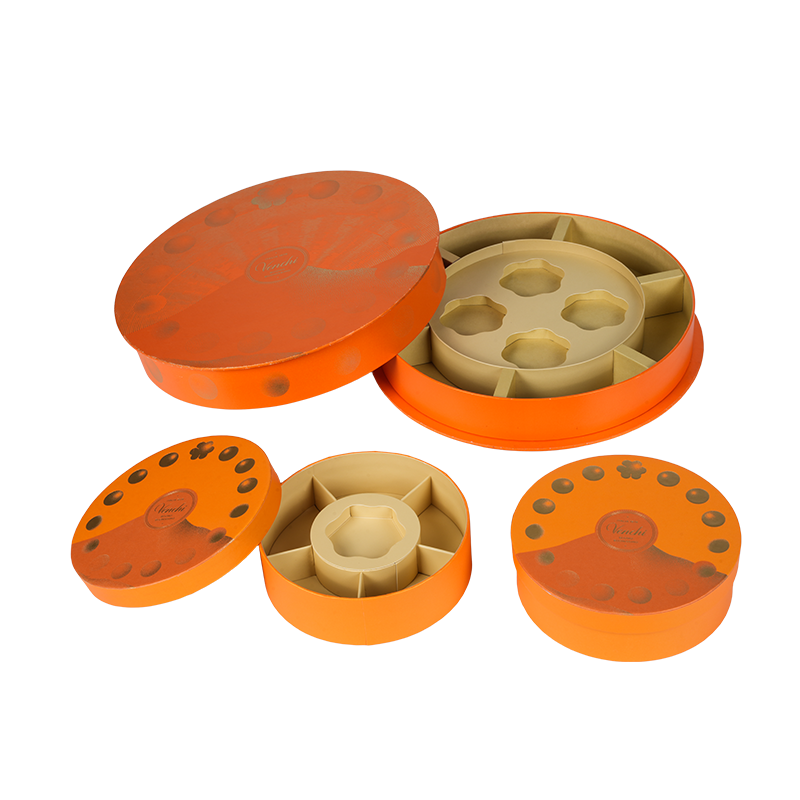

Packaging boxes with compartments, individual sections, or sealing lids make it easy to store candies at home or in the office. Consumers can take the desired portion without scattering, and portion control becomes easier.

Suitable for Retail Display

Standardized packaging boxes can be neatly stacked on shelves. Printed brand information and flavor labels are clear and easy for consumers to identify and select.

3. Value & Compliance: Supporting Sales and Branding

Enhanced Product Perception

Candies of the same quality appear more refined when paired with premium packaging boxes such as tin boxes or cultural-creative gift boxes. This supports differentiated pricing and distinguishes them from loose candy products.

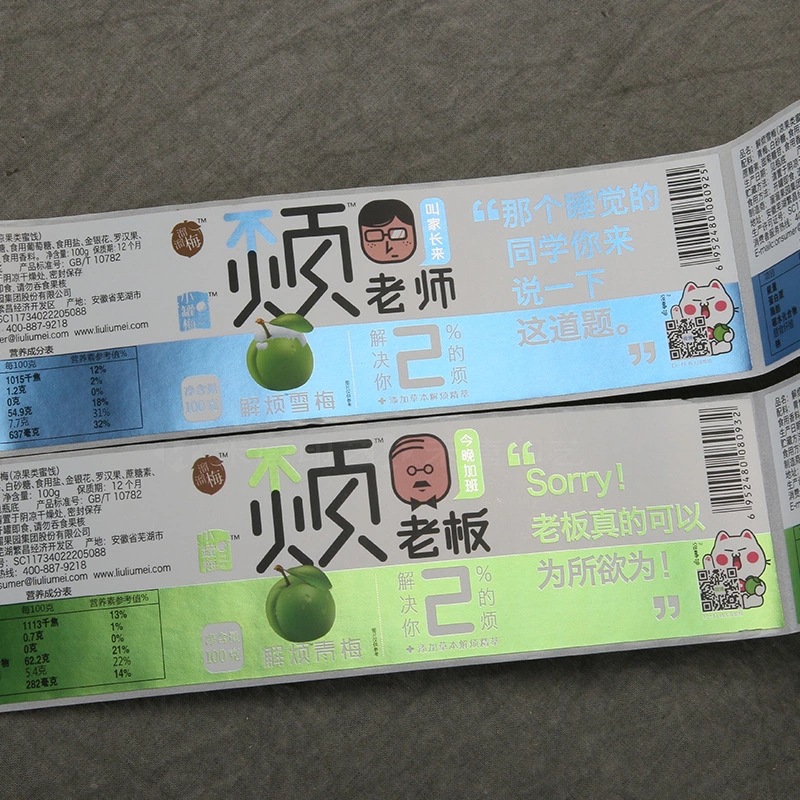

Compliance with Food Labeling Requirements

Packaging boxes can fully display ingredient lists, production dates, shelf life, allergen warnings, and other mandatory information, fulfilling food packaging regulations and reassuring consumers.

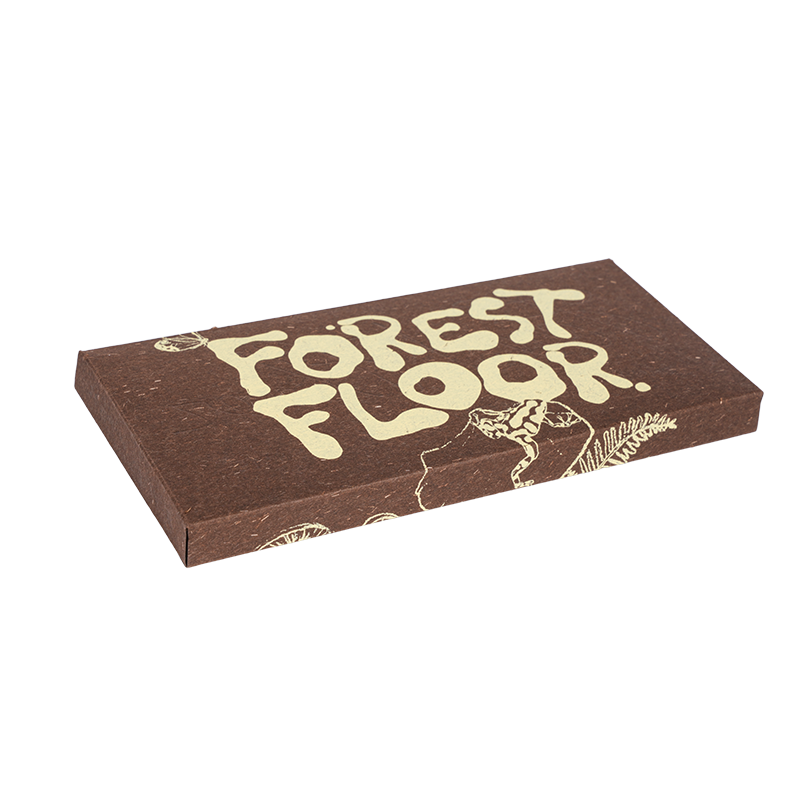

Stronger Brand Memory

Unique packaging designs—such as themed shapes or eco-friendly materials—attract attention while conveying brand concepts such as playfulness, premium quality, or health-oriented positioning, deepening consumer impression.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Moisture Control and Structural Stability for Candy Packaging Boxes

Candy packaging boxes face unique challenges related to moisture sensitivity and shape retention. High sugar content products are prone to stickiness and deformation when exposed to humidity, making outer packaging an indirect but important protective layer. Practical box designs focus on maintaining structural integrity to support inner wraps or trays, preventing compression that could compromise seals. In our production process, we often recommend film lamination or coated papers to improve short-term moisture resistance during transportation and storage.

Stable box geometry also helps maintain consistent stacking in retail displays, which is especially important for seasonal or promotional candy products with high turnover.

Internal Layout Design for Mixed Candy Assortments

Many candy packaging boxes contain mixed assortments with different shapes, weights, and wrapping types. Internal layout design plays a key role in preventing product movement and visual disorder after transport. Paper-based partitions and trays are widely used to separate items while remaining recyclable. With precise automatic die-cutting and mounting equipment, these internal components can be produced with consistent tolerances at scale, which we find essential for OEM candy brands running frequent batch orders.

- Grid-style inserts prevent collision between individually wrapped candies.

- Shallow trays support soft candies without deformation.

- Fixed compartments improve visual order for gift-oriented boxes.

Print Durability and Color Performance

Candy packaging boxes often rely on bright colors and dense graphics to attract attention, which places higher demands on print durability. Ink rub resistance and color stability are critical, especially for boxes handled frequently on shelves. Practical solutions include surface lamination and controlled ink coverage to prevent cracking at fold lines. In our automated printing lines, consistent color calibration helps ensure that vivid designs remain uniform across large production runs.

Common Surface Treatment Options

- Gloss lamination to enhance brightness and shelf impact.

- Matte lamination for reduced glare on premium candy boxes.

- Spot UV to highlight characters or brand elements.

Production Efficiency for High-Volume Candy Orders

Candy brands often face peak-season demand, requiring packaging boxes that can be produced quickly and consistently. Box structures compatible with automatic box-making and gluing machines significantly improve throughput and reduce labor dependence. From our perspective as a large-scale manufacturer with a 13,000-square-meter workshop, designs that flow smoothly through automated lines are key to meeting tight seasonal delivery schedules without compromising quality.

| Design Feature | Production Impact | Operational Benefit |

| Pre-glued Box Structure | Faster forming | Shorter packing time |

| Standardized Die-line | Stable output | Lower defect rate |

Quality Control in Clean Workshop Environments

Quality control for candy packaging boxes places special emphasis on cleanliness and surface integrity. Dust or adhesive residue can be particularly visible on bright or glossy designs. Operating within a clean workshop environment helps minimize contamination risks, while ISO9001-based management systems focus on process consistency rather than final inspection alone. By aligning automated equipment with trained operators, we aim to support reliable OEM production for candy brands with diverse packaging requirements.

This systematic approach ensures that candy packaging boxes maintain both functional performance and visual appeal across repeated production cycles.