Production Capacity Guarantee – Large-Scale Production

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Coffee Packaging Boxes Manufacturers and OEM Coffee Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Coffee Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Coffee Packaging Boxes Manufacturers

The core advantages of coffee packaging lie in freshness preservation, scenario adaptability, and regulatory compliance, ensuring stable product quality while meeting storage and sales requirements.

Core Function: Preserving Essential Coffee Quality

Oxygen and Moisture Barrier

Coffee packaging blocks oxygen and airborne moisture to prevent oxidation, spoilage, and clumping. This is especially important for maintaining the aroma of roasted beans.

Light and UV Protection

Most packaging formats, such as aluminum-foil composite bags and opaque canisters, shield the contents from UV exposure, preventing flavor degradation and helping extend shelf life.

Pressure Control and Degassing

Packaging equipped with a one-way valve allows roasted beans to release carbon dioxide while preventing outside air from entering. This avoids package swelling and helps maintain flavor stability.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Barrier Performance and Aroma Protection in Coffee Packaging Boxes

For coffee packaging boxes, structural protection is only one layer of value; aroma preservation is often the real challenge. Although the box itself is not in direct contact with coffee, its material and construction influence the performance of inner bags and valves. Rigid boxes with precise fitting can reduce unnecessary air exchange during transportation, minimizing pressure on one-way degassing valves. In our large-scale OEM production, we often coordinate box tolerances with inner packaging specifications to ensure the aroma-protection system works as intended.

Paperboard stiffness and lamination stability also matter, as deformation can compromise the seal integrity of inner packs when boxes are stacked for long periods in warehouses.

Structural Adaptation for Different Coffee Formats

Coffee packaging boxes must accommodate a wide range of formats, from flat-bottom bags to aluminum capsules and bottled cold brew. Practical box design focuses on internal space utilization and load distribution rather than decorative complexity. For example, capsule boxes often require internal partitions to prevent friction damage, while whole-bean coffee bags benefit from vertical structures that stabilize the center of gravity.

- Vertical box structures reduce shifting for valve-equipped coffee bags.

- Internal paper partitions protect capsules during vibration-heavy transport.

- Reinforced corners improve stacking safety for bottled coffee products.

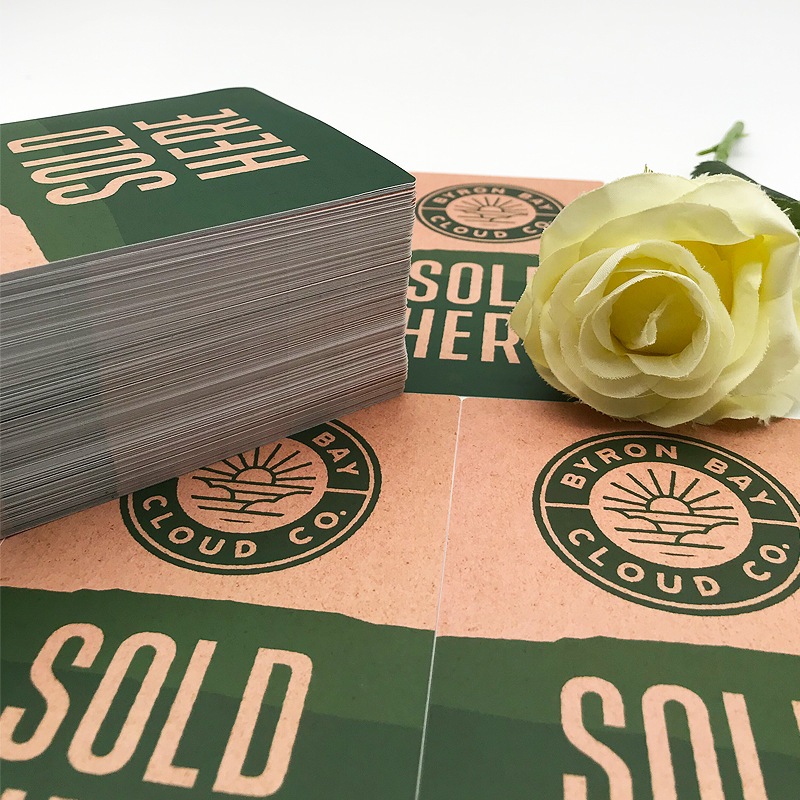

Print Process Choices for Coffee Brand Differentiation

Coffee packaging boxes rely heavily on tactile and visual cues to communicate origin, roast level, and brand identity. Matte lamination combined with subtle hot stamping is commonly used to convey premium positioning without overwhelming the surface. From a production standpoint, controlling film lamination temperature and pressure is critical to avoid warping, especially for dark, ink-heavy designs. With automated printing and laminating lines in our workshop, stable process parameters help maintain consistency across high-volume orders.

Commonly Applied Finishing Techniques

- Matte or soft-touch lamination for reduced glare on retail shelves.

- Hot stamping for logos or origin markers without excessive ink coverage.

- Spot UV to highlight roast profiles or flavor notes.

Efficiency Considerations in Mass Production

When coffee brands scale up, packaging box efficiency becomes a key cost factor. Designs compatible with automatic die-cutting and box-making machines reduce manual intervention and error rates. Pre-glued box structures shorten assembly time at filling facilities, improving overall supply chain efficiency. From our perspective as a manufacturer with 13,000 square meters of workshop space, automation-friendly designs are essential to meeting tight delivery schedules without compromising quality.

| Box Design Feature | Production Impact | Operational Benefit |

| Pre-glued Structure | Faster forming | Reduced packing time |

| Standardized Die-line | Lower setup errors | Stable batch quality |

Quality Control Focus Points for Coffee Packaging Boxes

Quality control in coffee packaging boxes emphasizes dimensional accuracy and surface durability. Minor deviations can lead to misalignment with inner packaging or retail display issues. ISO9001-based inspection systems typically prioritize die-cut precision, glue strength, and surface abrasion resistance. In our clean workshop environment, controlled conditions help reduce dust contamination, which is particularly important for dark-colored coffee boxes where surface flaws are more visible.

By aligning automated equipment with experienced operators, we aim to deliver packaging that supports both brand image and long-term supply stability, even under large-volume OEM requirements.