Production Capacity Guarantee – Large-Scale Production

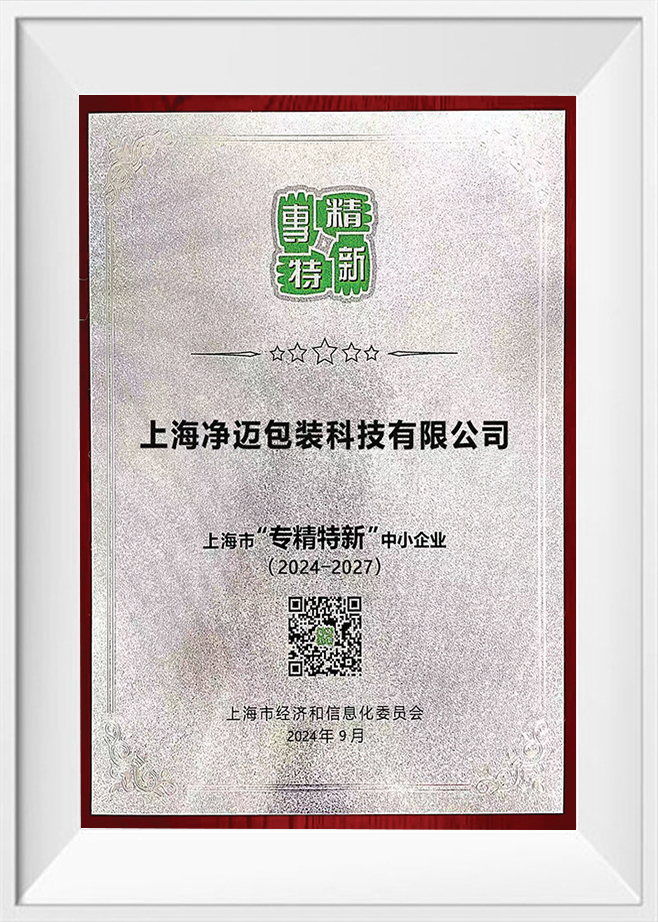

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Edible Oil Packaging Boxes Manufacturers and OEM Edible Oil Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

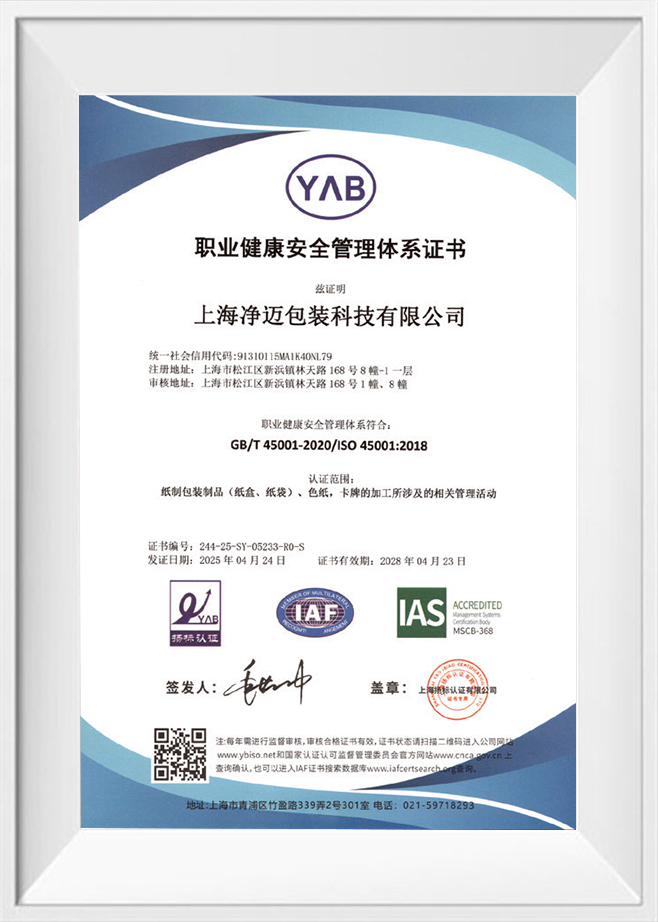

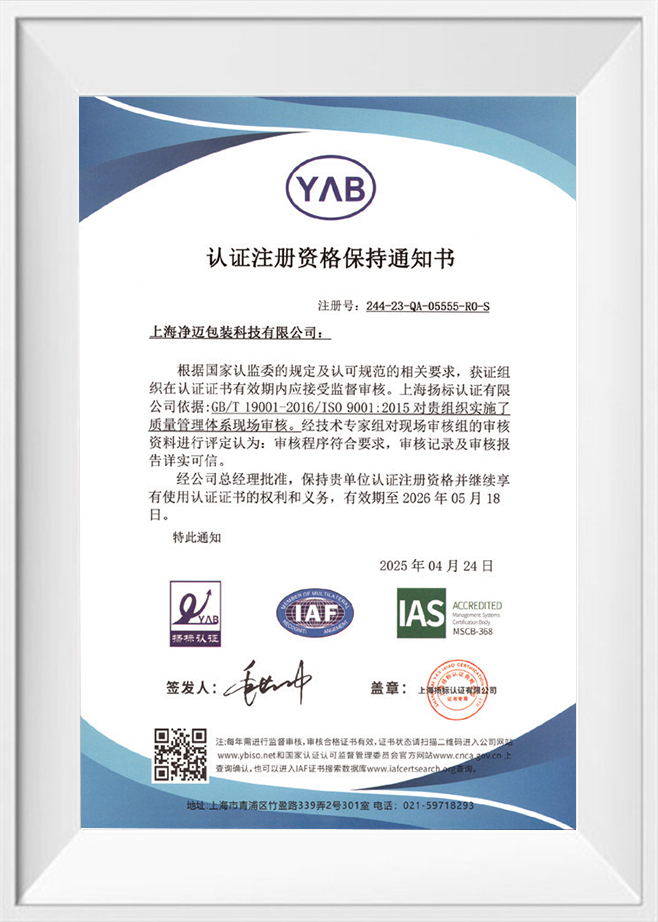

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

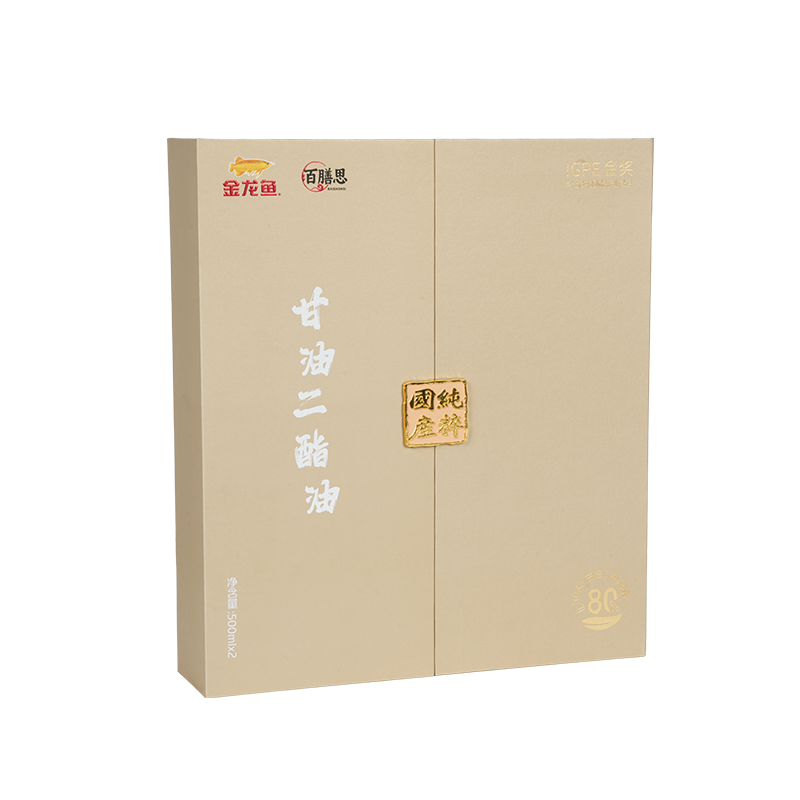

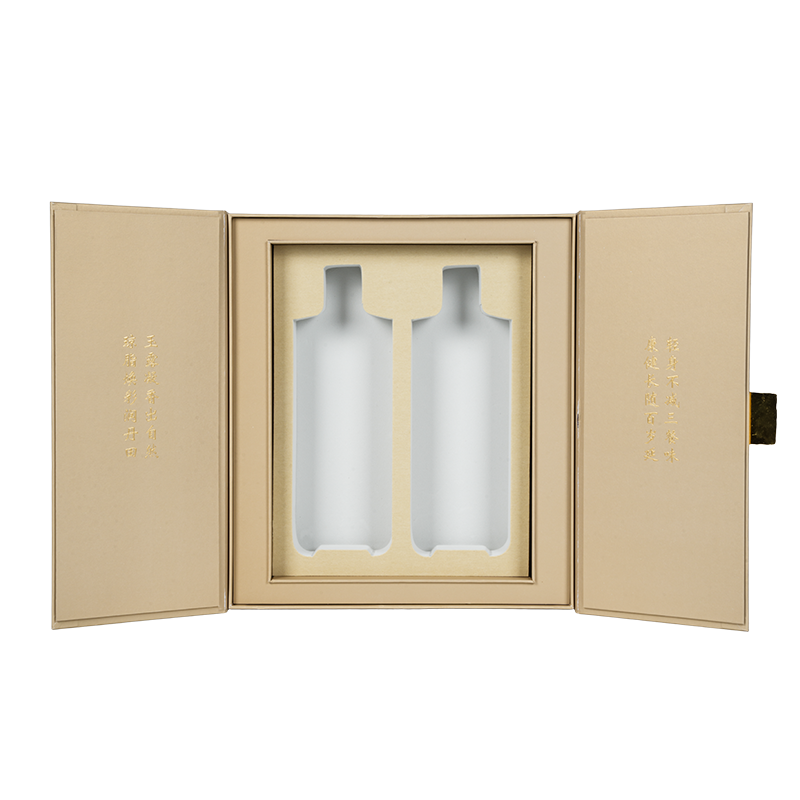

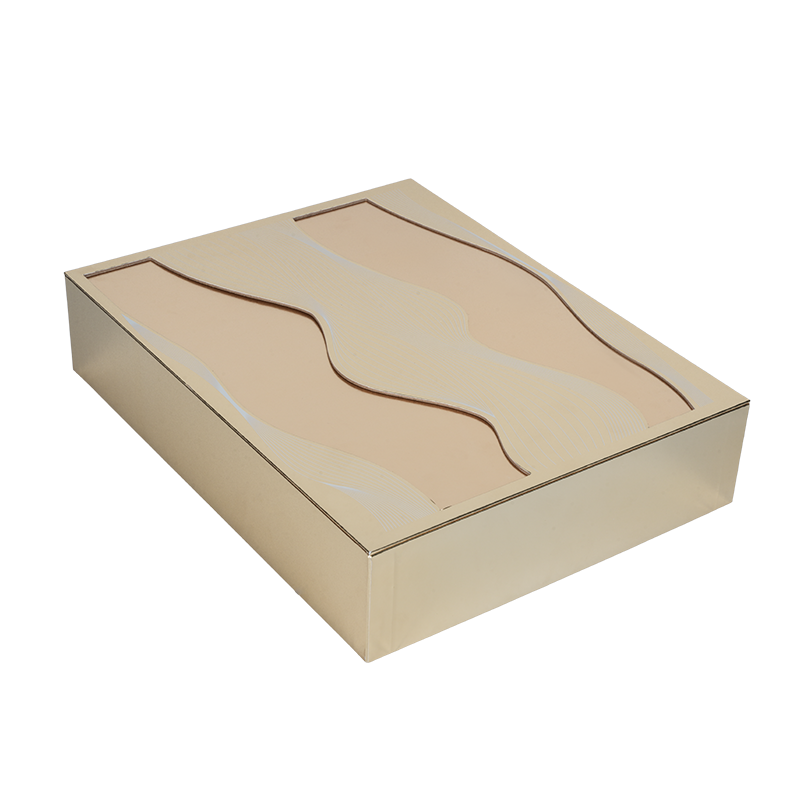

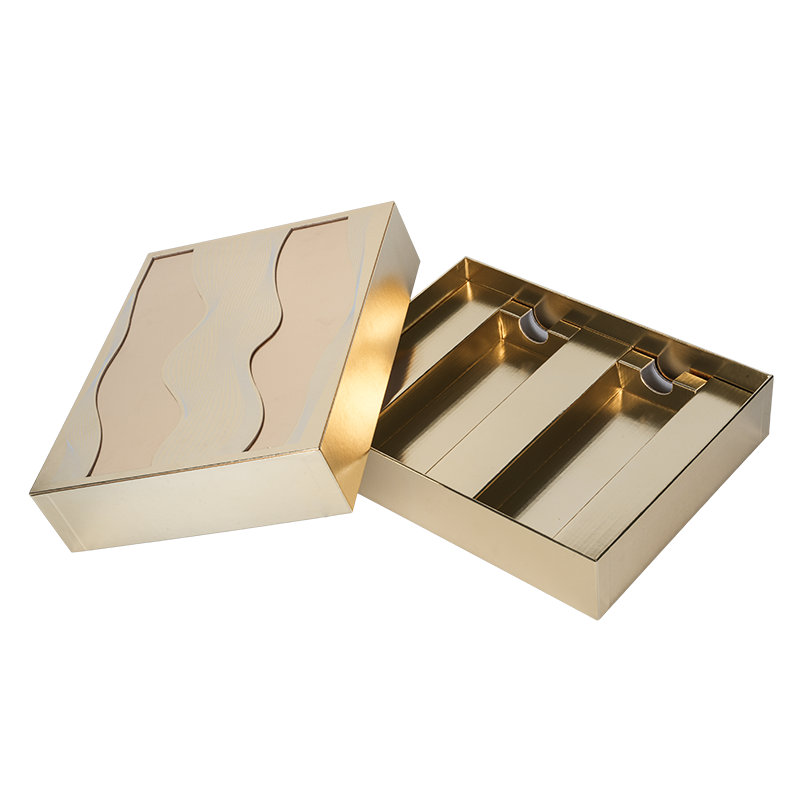

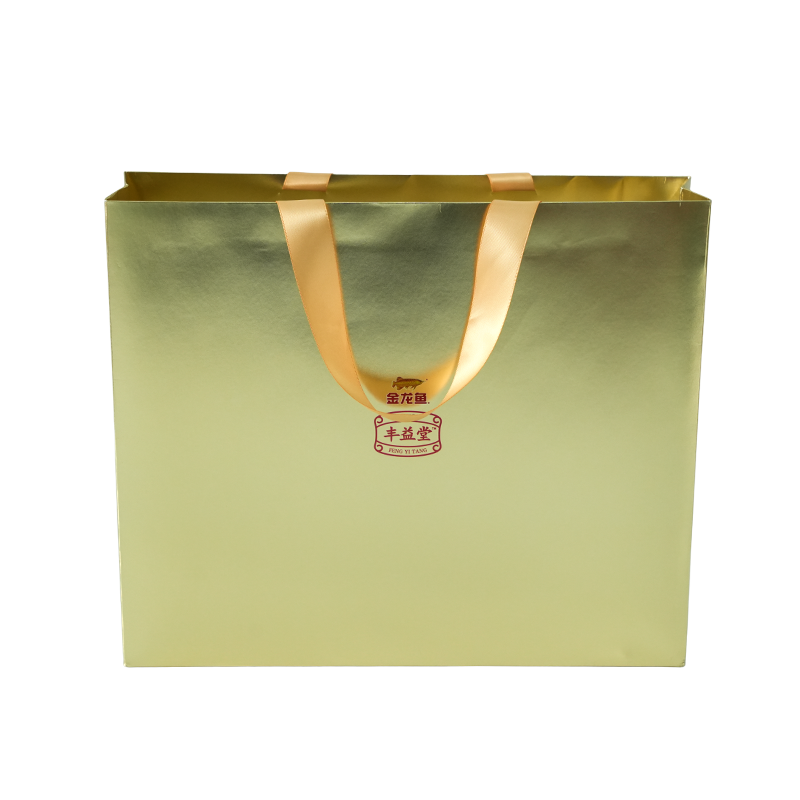

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Edible Oil Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Edible Oil Packaging Boxes Manufacturers

Specially engineered to combat oil degradation—rancidity, light-induced spoilage, leakage, and odor absorption—ensuring quality from production to pantry.

1. Core Protection: Preserve Oil Integrity

Oxygen Barrier Against Rancidity: High-barrier materials (PET/PE multilayer bottles, metal tins) significantly reduce oxygen ingress—critical for delicate oils high in unsaturated fats (e.g., walnut, flaxseed, avocado oil).

Light-Proof Design: Amber or opaque containers (glass, coated tin, UV-blocking PET) shield against UV rays, preventing vitamin loss, flavor deterioration, and “off” odors (e.g., rancid or “painty” notes).

Leak-Proof & Hygienic: Secure closures (tamper-evident screw caps, food-grade pump dispensers) + seamless bottle construction prevent seepage and contamination during transport or storage.

Odor & Moisture Resistant: Non-porous, neutral-odor materials avoid flavor migration—preserving the oil’s authentic aroma and taste.

2. Practical Usability: Daily Kitchen & On-the-Go Needs

Precision Dispensing: Integrated pour spouts or pump heads enable controlled portioning—minimizing spills and kitchen mess; ideal for dressings, cooking, or dietary use.

Space-Smart Storage: Stable, upright designs (round/rectangular bottles, stackable tins) optimize cabinet or countertop space; corrosion- and heat-resistant options suit varied environments.

Logistics-Optimized: Uniform, durable packaging supports safe pallet stacking and long-haul shipping—reducing leakage and breakage in e-commerce or wholesale distribution.

3. Compliance & Brand Value

Regulatory Transparency: Ample labeling area for oil type, origin, extraction method (cold-pressed/expeller), smoke point, nutrition facts, allergen info, and certifications (e.g., organic, non-GMO)—ensuring full compliance and consumer trust.

Tiered Positioning:

– Premium tier: Glass bottles or embossed metal tins with gift boxes—elevating artisanal, cold-pressed, or imported oils.

– Value tier: Lightweight recyclable PET—cost-efficient for everyday cooking oils without compromising safety.

Brand Recognition: Distinctive bottle shapes, color coding (e.g., gold for luxury, green for organic), and prominent logo placement strengthen shelf impact and loyalty.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Barrier Performance and Shelf-Life Predictability

For bulk buyers, edible oil packaging selection directly influences shelf-life stability forecasts. Oils rich in polyunsaturated fatty acids are particularly sensitive to oxygen transmission rates (OTR). High-barrier multilayer structures can reduce oxidation speed by more than half compared to standard single-layer packaging, enabling more accurate inventory turnover planning and fewer quality-related claims.

In our experience working with large distributors, aligning barrier performance with oil type early in the procurement phase significantly reduces downstream risk without inflating packaging costs.

Light Exposure Control Beyond “Opaque vs Transparent”

Light protection is not binary. UV, blue light, and visible spectrum exposure each affect oil stability differently. Amber glass and coated tins primarily block UV, while advanced UV-blocking PET can attenuate shorter wavelengths responsible for vitamin degradation.

- UV-blocking layers help preserve tocopherols and polyphenols

- Opaque coatings reduce photo-oxidation during retail lighting exposure

- Consistent light shielding improves sensory stability across batches

We often recommend matching light-barrier performance to the intended retail environment, not just storage conditions.

Leakage Risk as a Logistics Cost Variable

Leakage is rarely just a packaging defect—it is a logistics multiplier. Oil seepage during transport contaminates secondary cartons, increases rejection rates, and disrupts automated warehousing systems. Seamless bottle bodies combined with tamper-evident closures materially reduce claim frequency in long-haul shipments.

From pallet compression tests to vibration simulations, packaging engineered for transport resilience consistently lowers total landed cost, which is why we emphasize closure integrity during early sampling.

Odor Neutrality and Flavor Integrity

Oils readily absorb ambient odors, especially during storage alongside spices, detergents, or corrugated materials. Non-porous, food-grade inner materials are critical in preventing flavor migration.

Odor-neutral packaging preserves the oil’s native aroma profile, which is increasingly important for premium and cold-pressed oils positioned on sensory quality rather than price.

Dispensing Design and Consumption Accuracy

Precision dispensing is not only a consumer convenience feature—it influences usage rate and repurchase cycles. Controlled-flow spouts and pump systems help users avoid over-pouring, particularly in dietary or functional oil applications.

- Improved portion control reduces waste perception

- Cleaner dispensing minimizes secondary contamination

- Enhanced user experience supports brand loyalty

Packaging Geometry and Storage Efficiency

The external geometry of edible oil packaging box directly affects warehousing density and retail shelf utilization. Rectangular or stackable formats often outperform round bottles in both pallet efficiency and shelf-facing consistency.

| Shape | Stacking Efficiency | Shelf Stability |

|---|---|---|

| Round Bottle | Medium | Good |

| Rectangular Bottle | High | Excellent |

| Metal Tin | High | Excellent |

Scaling Production Without Compromising Consistency

Large-volume procurement demands more than capacity—it requires process repeatability. Automated printing, die-cutting, laminating, and box-forming systems reduce batch variance while supporting rapid scale-up.

A controlled production environment with ISO-aligned quality management ensures that packaging performance remains consistent from pilot runs to mass production. This is precisely where we see bulk buyers gain long-term supply stability.