Production Capacity Guarantee – Large-Scale Production

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Flexible Food Packaging Manufacturers and OEM Food Flexible Pouch Packaging Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

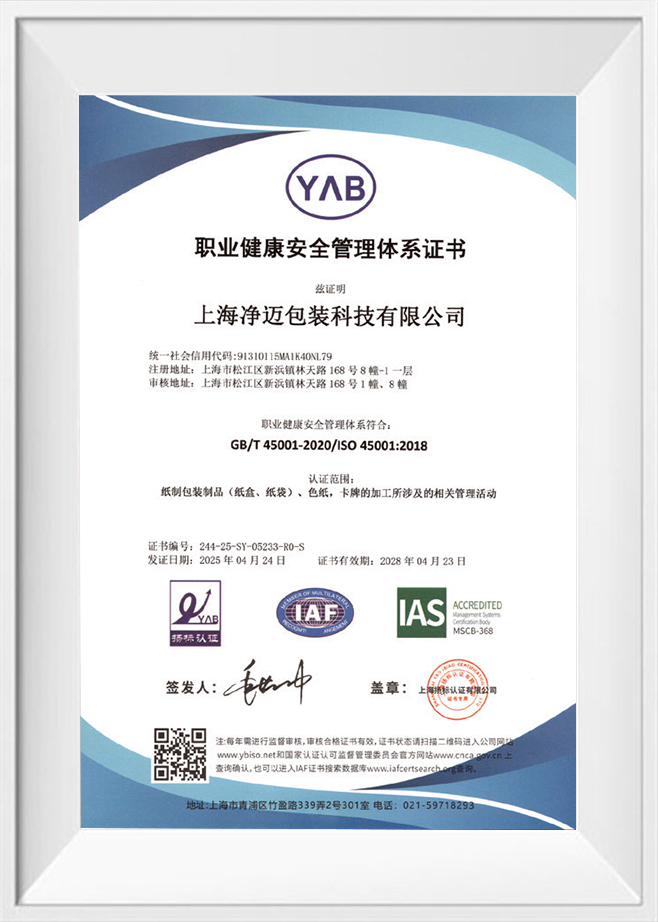

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Food Flexible Packaging Bags, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Flexible Food Packaging Manufacturers

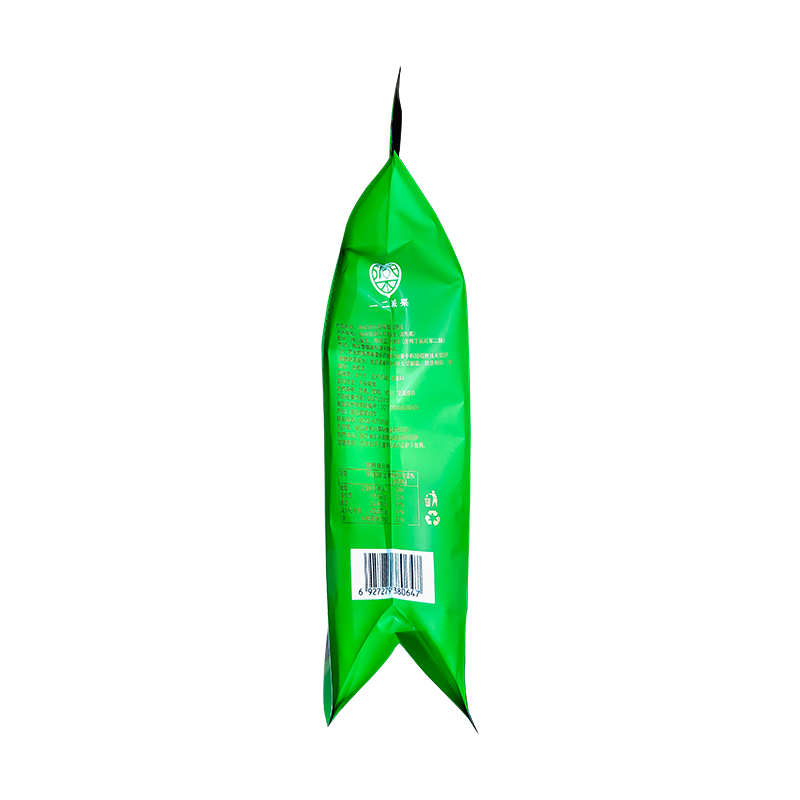

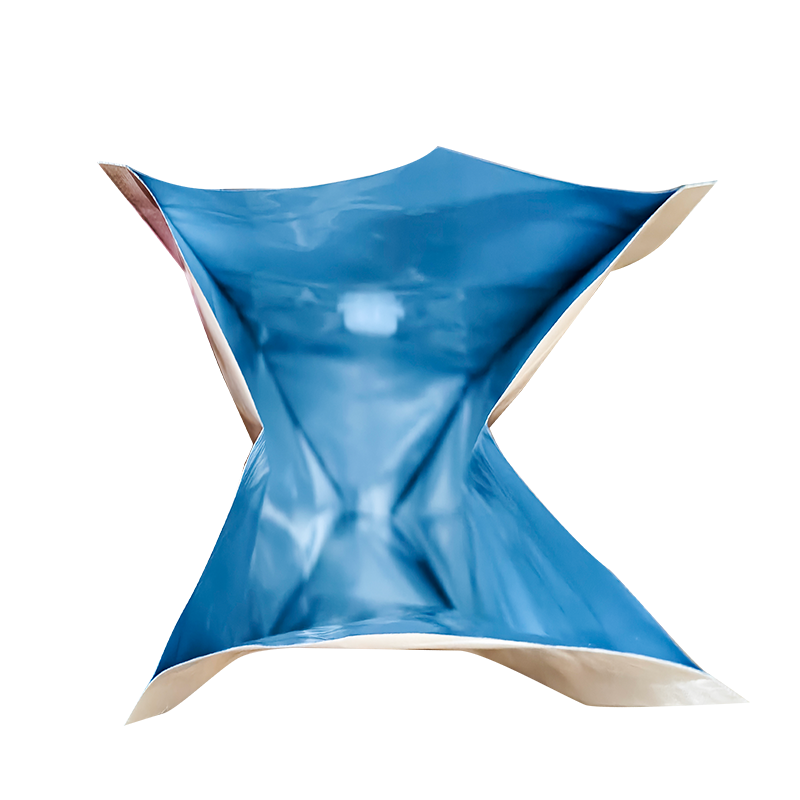

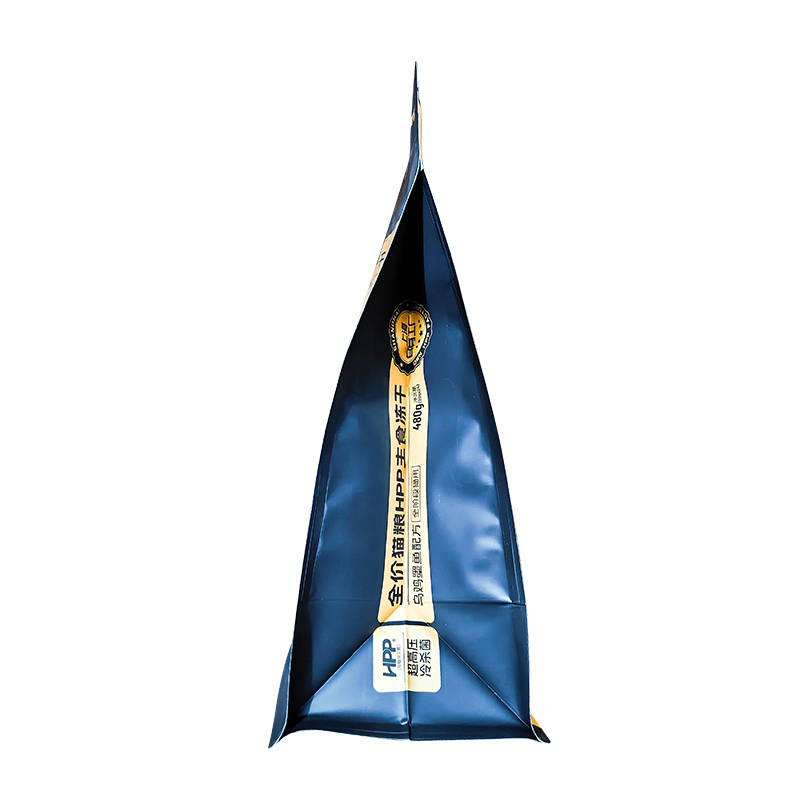

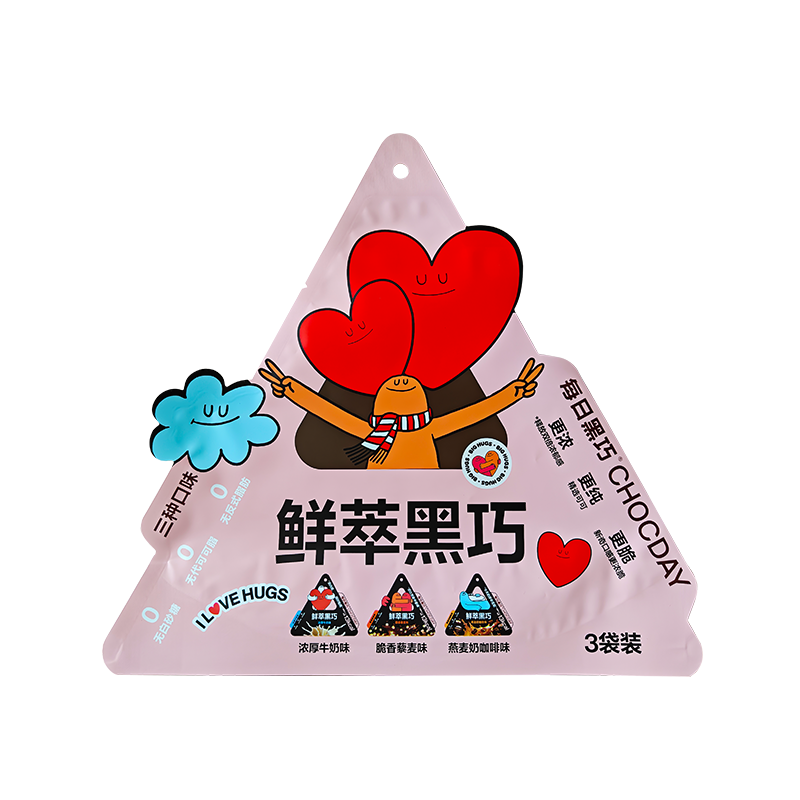

Flexible food packaging covers flexible, multi-layer pouches designed to directly contain food products — including three-side-seal bags, stand-up pouches, back-seal pouches, and custom-shaped formats. Commonly used for coffee beans, tea leaves, nuts, dried fruits, seasonings, instant soups, and pet food, these packages prioritize freshness retention, portability, and retail visibility.

Constructed from laminated films (e.g., PET/AL/PE, BOPP/CPP), they offer balanced performance in oxygen/moisture barrier, heat seal integrity, and print quality. Functional features such as tear notches, resealable zippers, degassing valves, or clear windows can be integrated. Their lightweight design reduces shipping costs, while their pliability supports high-speed filling and labeling automation — making them a standard solution across modern food supply chains.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

What Are Flexible Food Packaging Bags and Why They Matter

Food Flexible Pouch Packaging are lightweight, adaptable packaging solutions made from multi-layer materials such as plastic films, aluminum foil, and paper composites. They are designed to protect food products from moisture, oxygen, light, and contamination while extending shelf life. Compared with rigid packaging, flexible bags reduce material usage, lower transportation costs, and offer greater design freedom for branding and functionality.

Common Types of Flexible Food Packaging Bags

Different food categories require different packaging structures. Choosing the right bag type directly affects product freshness, usability, and consumer experience.

- Stand-up pouches: Ideal for snacks, dried foods, and beverages, offering strong shelf presence and resealable features.

- Flat pouches: Cost-effective solutions for single-use or portioned food products.

- Vacuum bags: Designed to remove air and extend shelf life for meat, seafood, and cooked foods.

- Retort pouches: Heat-resistant packaging suitable for ready-to-eat and sterilized food products.

Material Structure and Functional Performance

Flexible Food Packaging rely on layered material structures to achieve specific performance goals. Each layer plays a functional role, balancing protection, sealing strength, and print quality.

| Material Layer | Primary Function |

| PET / BOPP | High clarity and printability |

| Aluminum Foil | Strong barrier against light and oxygen |

| PE / CPP | Heat sealing and food contact safety |

Customization and Branding Advantages

Flexible food packaging bags offer extensive customization options that support brand differentiation. Printing, shape, size, and functional features can all be tailored to product positioning and market needs.

Key Customization Options

- High-definition gravure or digital printing for strong visual impact

- Zippers, tear notches, and spouts for improved consumer convenience

- Custom shapes and sizes to match product volume and shelf display

Reliable Manufacturing for Large-Scale Supply

Shanghai Jingmai Packaging Technology Co., Ltd. is a professional manufacturer of flexible food packaging, providing OEM and custom solutions for global food brands. The company’s production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, with a workshop area of 13,000 square meters and a workforce of 180 employees.

Equipped with advanced printing, laminating, die-cutting, and bag-making machines, and supported by a newly built clean workshop, the company can efficiently handle large-volume orders while meeting strict food packaging quality requirements. Certification under the ISO9001 quality management system ensures stable processes and consistent product performance.

One-Stop Service from Design to Delivery

Beyond manufacturing, Shanghai Jingmai Packaging Technology Co., Ltd. provides a complete one-stop service for flexible food packaging bags. This includes packaging design, sampling, material selection, procurement, mass production, and logistics coordination.

This integrated approach helps food brands shorten development cycles, control costs, and ensure packaging consistency across different markets, making Flexible Food Packaging a practical and scalable solution for modern food businesses.