Production Capacity Guarantee – Large-Scale Production

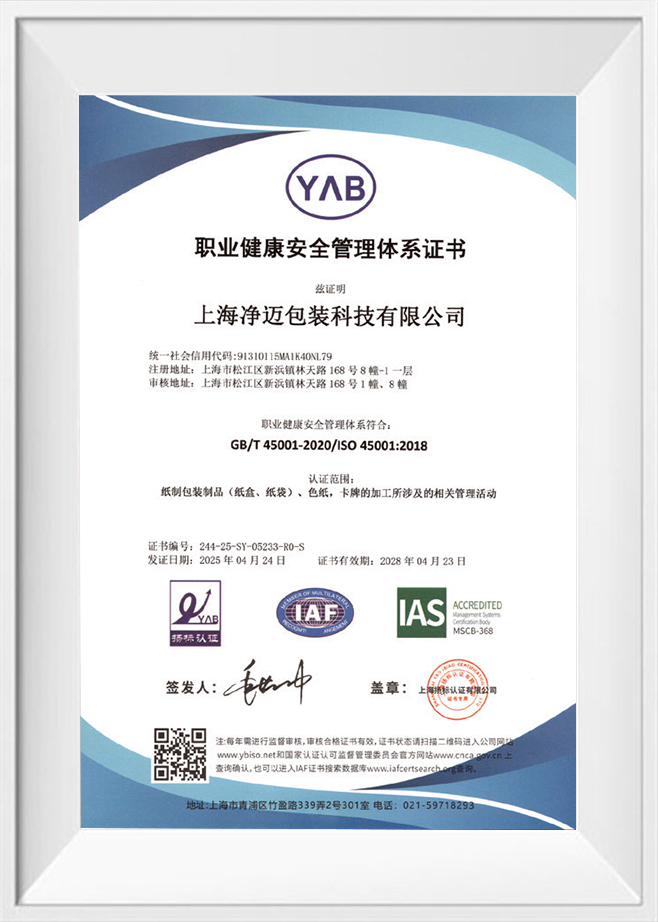

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Takeaway Packaging Bag Manufacturers and OEM Paper Takeout Bags Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

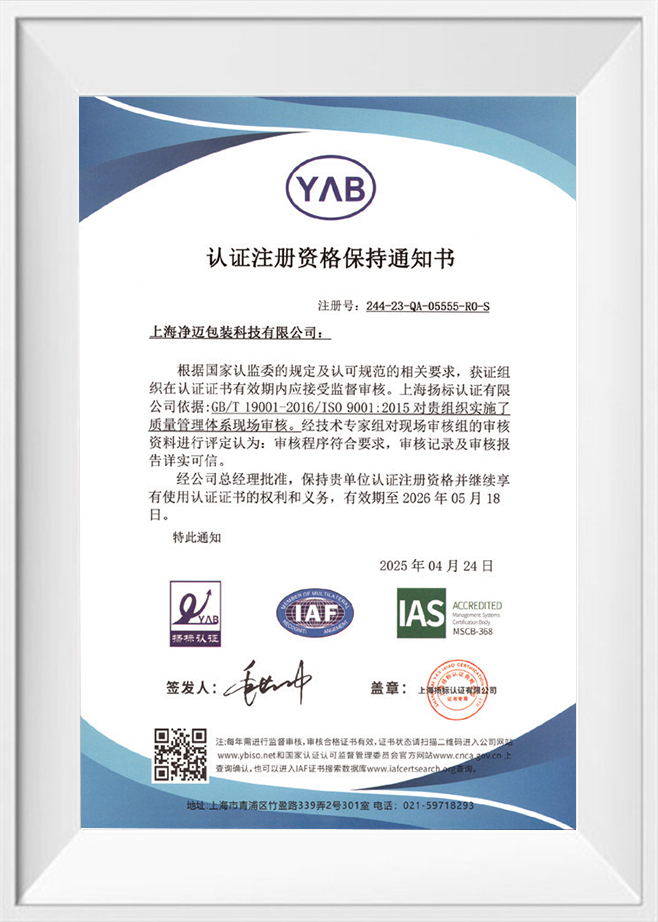

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

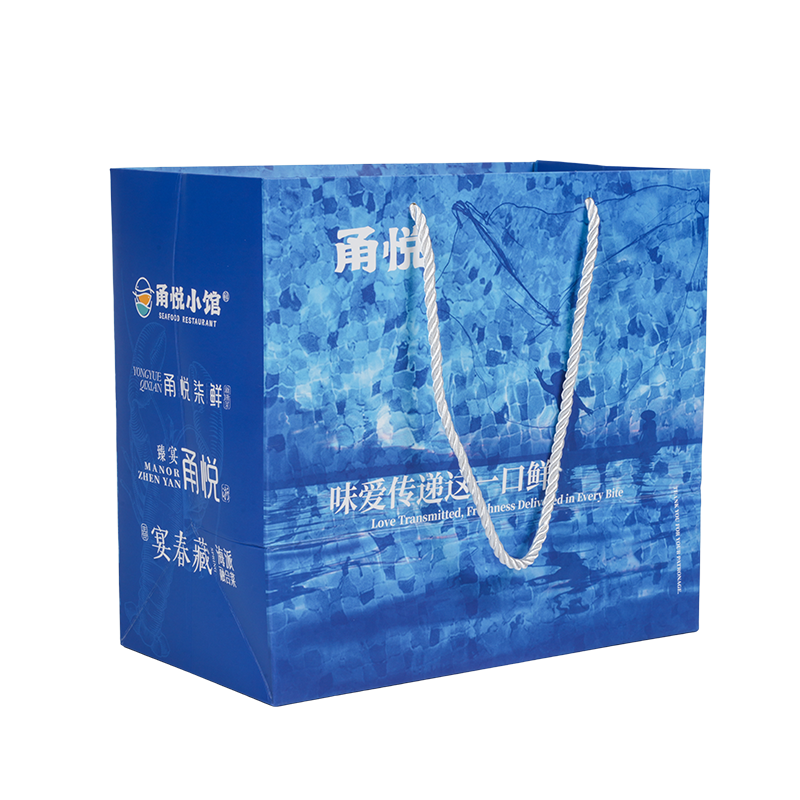

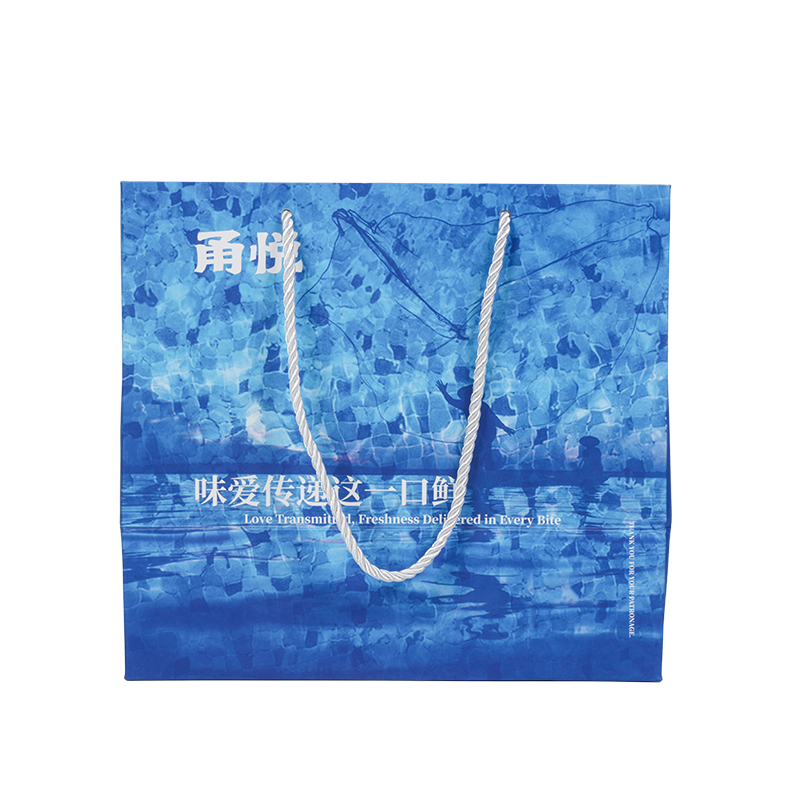

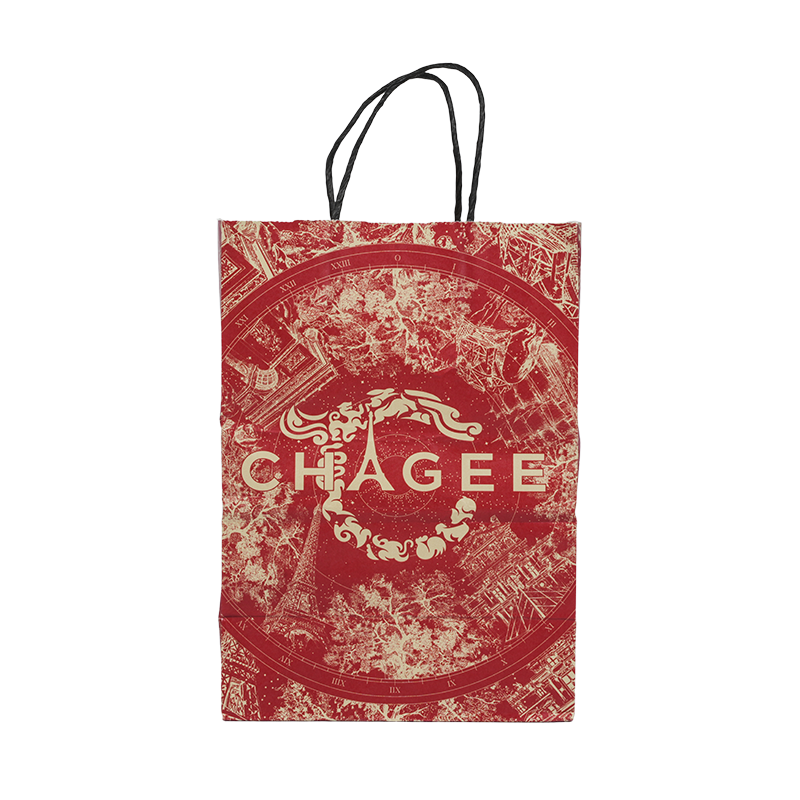

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Take Away Paper Bags Wholesale, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Takeaway Packaging Bag Manufacturers

Engineered for real-world delivery demands—steam release, oil resistance, durability, and brand visibility—without compromising food safety or sustainability.

1. Core Protection: Match Meal-Specific Needs

Breathable Design: Natural fiber materials (unbleached kraft, recycled paper) allow controlled vapor escape—keeping fried chicken, burgers, and skewers crisp by preventing sogginess from trapped steam.

Grease & Stain Resistant: Heavy-duty or PE-coated kraft paper blocks oil penetration—ideal for fries, dough sticks, and saucy items—keeping hands and bags clean.

High Tensile Strength: Stiff, tear-resistant construction supports full meal sets (containers + drinks) without ripping or bottoming out during transit.

Food-Safe Compliance: 100% food-grade, odorless, and free of PFAS/BPA—minimizing contamination risk and meeting global food contact regulations.

2. Delivery-Optimized Usability

Easy Carry & Stack: Integrated reinforced handles enable secure hanging on delivery scooters; flat-bottom design allows stable stacking—improving rider efficiency.

Space-Smart & Versatile: Fold-flat for storage; fits standard container sizes; doubles as direct serving pouch for bread, pastries, or snacks—reducing secondary packaging waste.

Temperature Adaptive: Heat-tolerant surface resists softening with hot items; retains flexibility in cold conditions—performing reliably year-round.

3. Brand & Sustainability Value

Eco-Credibility: Fully recyclable & compostable (where facilities exist)—aligns with consumer demand for green F&B brands and supports ESG messaging.

Premium Perception: Natural kraft texture conveys artisanal, health-conscious, or minimalist brand identity; clean print surface ensures sharp logo/branding—ideal for cafes, healthy bowls, or boutique bakeries.

Cost-Efficient Scalability: More affordable than non-woven bags; customizable by weight (80g–150g), coating (matte PE, water-based barrier), and finishing—perfect for SMEs and multi-unit chains.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Balancing Steam Release and Oil Resistance in Takeaway Paper Bags

In high-volume takeaway operations, managing steam without sacrificing oil resistance is a recurring challenge. Natural fiber structures such as unbleached kraft allow micro-level vapor escape, which helps fried items maintain surface texture. At the same time, selective surface treatments or inner PE layers block grease migration.

The key is not maximum breathability, but controlled permeability. Excessive ventilation accelerates heat loss and drying, while insufficient release traps condensation. In our production practice, we fine-tune paper density and coating weight to align with specific menu profiles rather than using a one-size-fits-all solution.

Paper Strength Metrics That Actually Matter in Delivery Scenarios

Bulk buyers often compare grammage (GSM) alone, but real-world delivery stresses reveal a broader set of indicators. Tensile strength, tear resistance, and bottom burst strength collectively determine whether a bag survives multi-stop delivery.

| Indicator | Operational Impact | Typical Risk if Underspecified |

|---|---|---|

| Tensile strength | Handles dynamic loads during carrying | Side tearing near handles |

| Bottom burst strength | Supports stacked containers | Bag bottom collapse |

| Tear resistance | Prevents propagation of small cuts | Rapid failure after minor damage |

Food-Contact Compliance: What Procurement Teams Should Verify

Compliance claims can vary significantly between suppliers. For takeaway packaging bags, buyers should verify not only finished-bag certification but also upstream material conformity. PFAS- and BPA-free declarations should apply to coatings, inks, and adhesives, not just base paper.

Common Oversights in Documentation

- Certificates covering paper stock but excluding printing inks or laminating films

- Regional compliance only, without alignment to export destination regulations

- Test reports older than the current material batch

From our side, maintaining a clean workshop and ISO9001-aligned traceability allows us to keep these risks visible and manageable at scale.

Handle Design and Reinforcement for Scooter-Based Delivery

Delivery platforms increasingly rely on scooter hooks and handlebars rather than hand-carrying alone. This shifts stress concentration to the handle junction. Reinforced twisted-paper handles or patch-reinforced flat handles distribute load more evenly across the bag wall.

A practical benchmark is whether the handle assembly sustains repeated hanging cycles without fiber separation. We often advise bulk buyers to request cyclic load testing rather than single static tests when evaluating samples.

When Take Away Paper Bags Replace Secondary Packaging

Well-structured paper takeout bags can function as both transport packaging and point-of-sale serving pouches. Flat-bottom construction and stiffness retention allow direct placement on counters for bread, pastries, or snacks, eliminating trays or inner wraps.

This approach reduces material count and simplifies logistics, but only works if dimensional tolerances are consistent. In large-scale production, automated die-cutting and box-making precision become decisive factors—areas where our integrated production lines help stabilize output quality.