Production Capacity Guarantee – Large-Scale Production

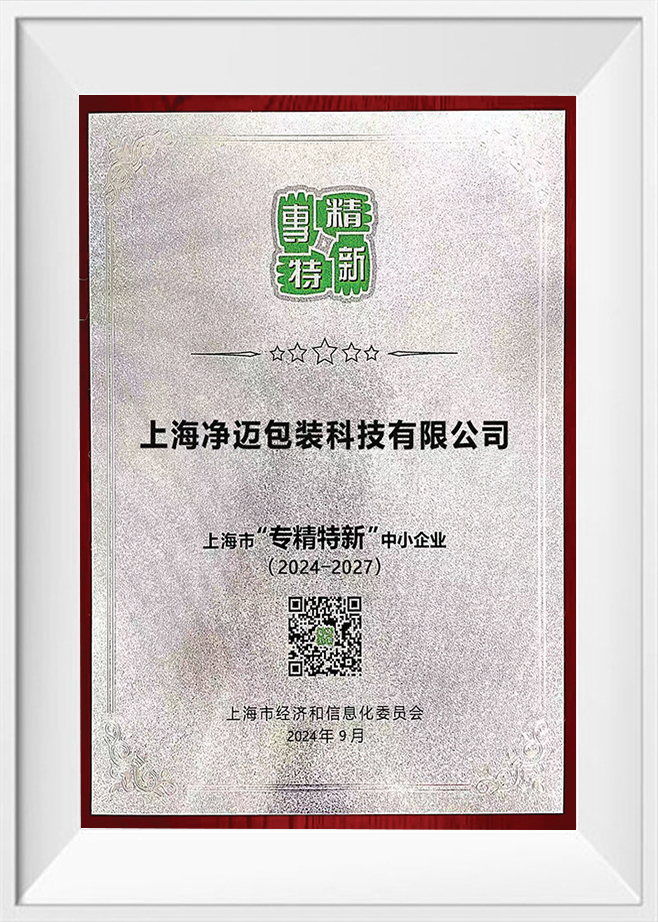

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom General Gift Packaging Boxes Manufacturers and OEM General Gift Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

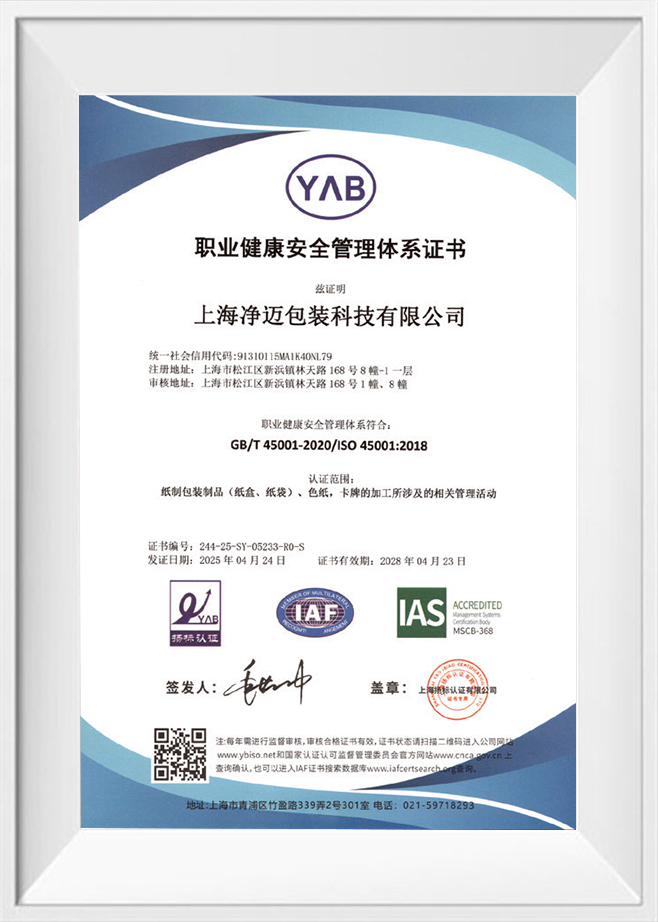

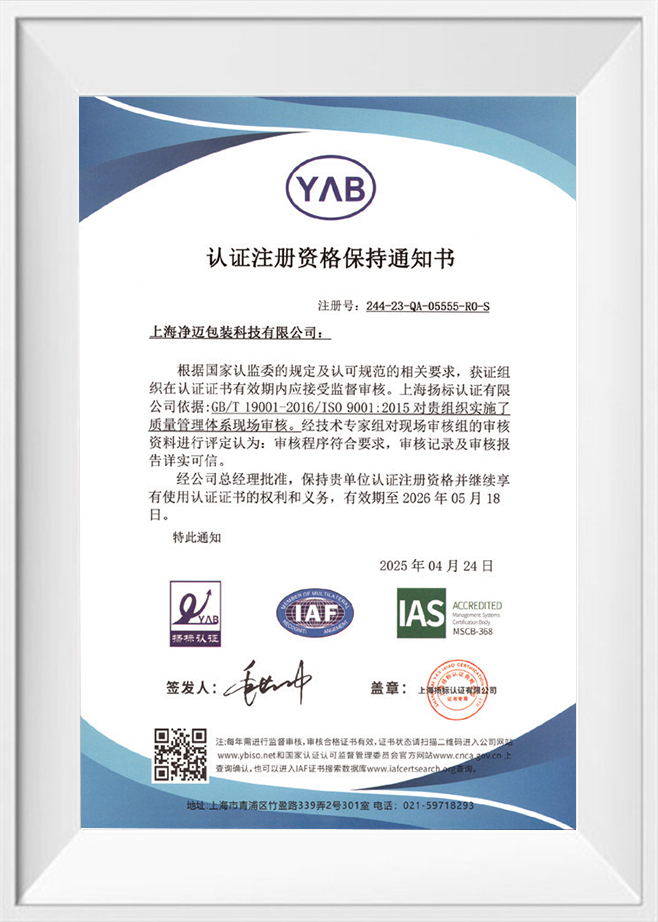

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

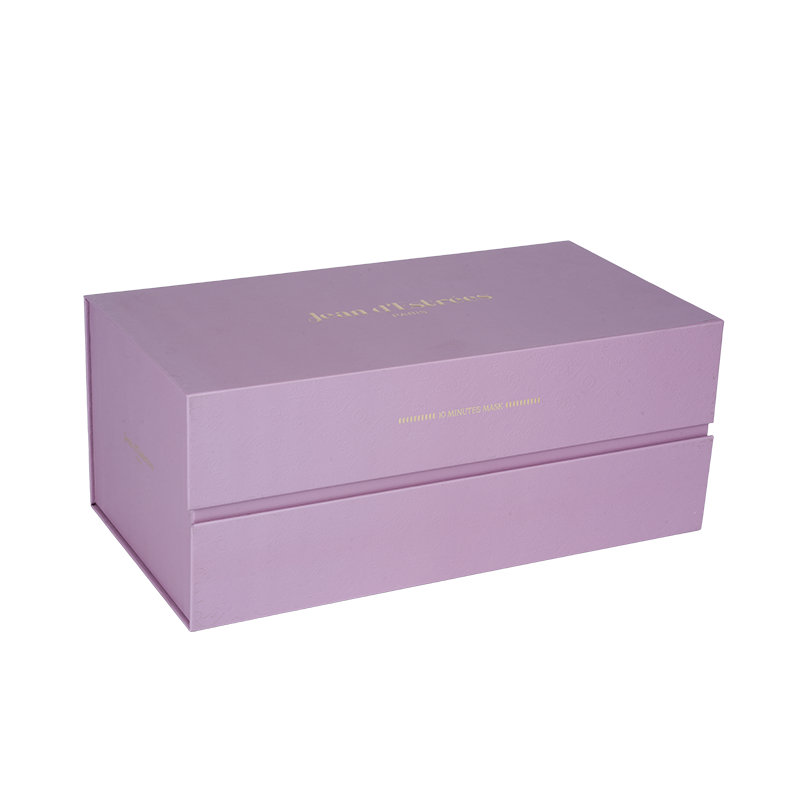

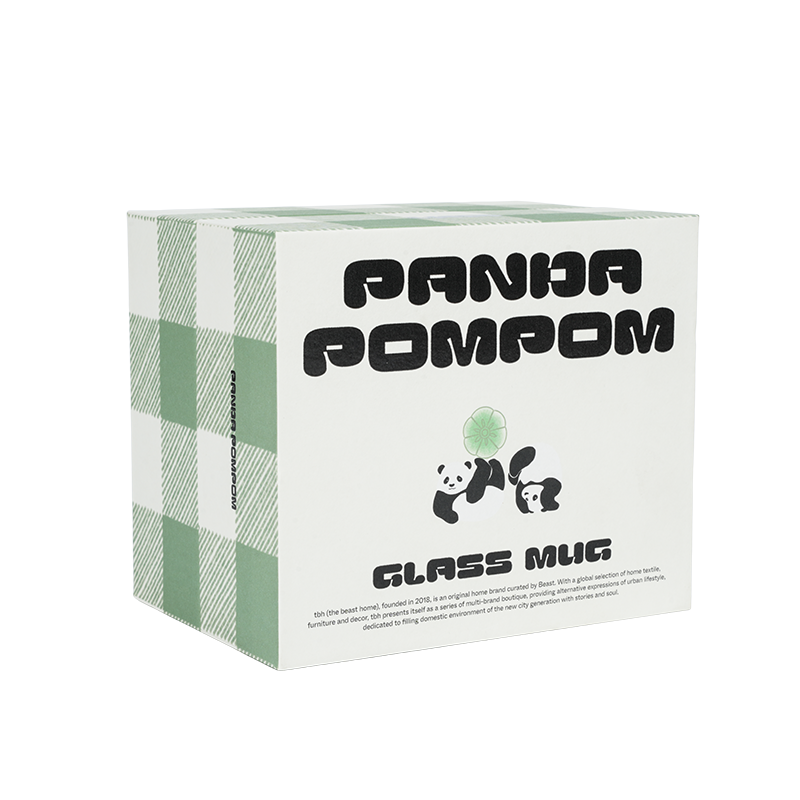

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, General Gift Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

General Gift Packaging Boxes Manufacturers

General-purpose packaging refers to versatile containers not limited to specific products—designed for broad applicability, with standardization, multi-functionality, and low cost as core features.

Features

Standard Sizes: Aligned with common logistics units (e.g., pallet, container dimensions) for easy stacking, handling, and warehousing—improving supply chain efficiency.

Versatile Materials: Commonly made from plastic, white cardboard, kraft paper, or corrugated board—meeting basic protection needs (moisture-resistant, dust-proof, impact-absorbing) and supporting recyclability.

Practical Functionality: Provides essential physical protection during transit and storage, maintaining product cleanliness and integrity.

Simple & Adaptable Design: Typically plain color or minimal texture, with only core branding (logo, brand color). Common box styles: lid-and-base, tuck-end, mailer (airplane-style), and snap-lock bottom—internal dividers easily customizable.

Advantages

Cost Efficiency: Mass production reduces tooling, printing, and processing costs per unit—ideal for budget-conscious businesses.

Streamlined Inventory: Eliminates need for product-specific custom packaging—simplifying stock management and minimizing waste from product updates.

User-Friendly Operation: Easy assembly and closure (e.g., one-piece mailer boxes, fold-flat design)—speeds up packing for sellers and unboxing for customers.

Eco-Friendly: Primarily uses recyclable, widely accepted materials—supporting sustainable practices and green consumer expectations.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Understanding Customizable Interiors in General Gift Packaging Boxes

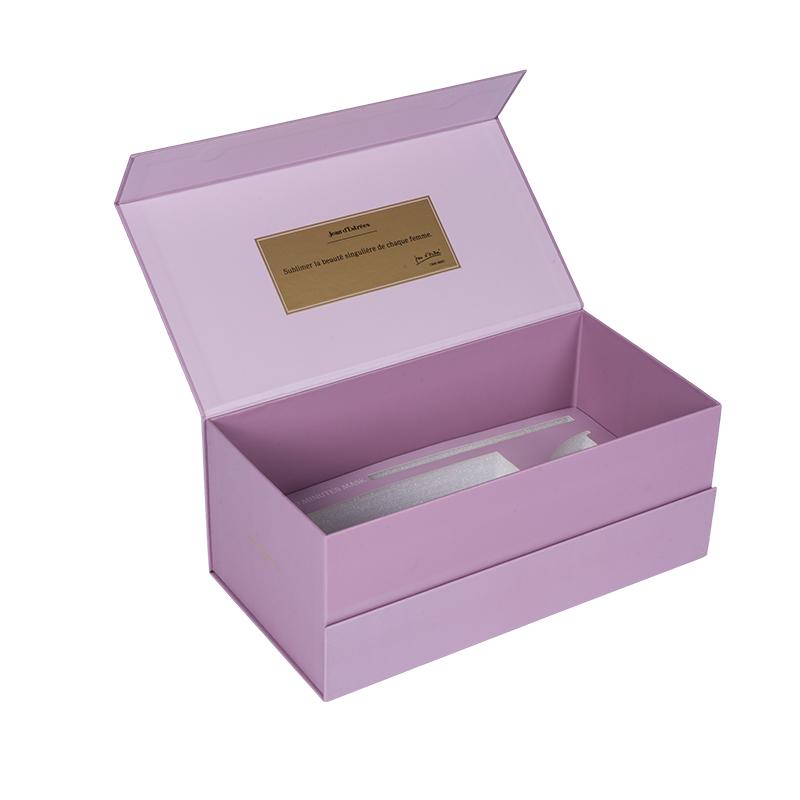

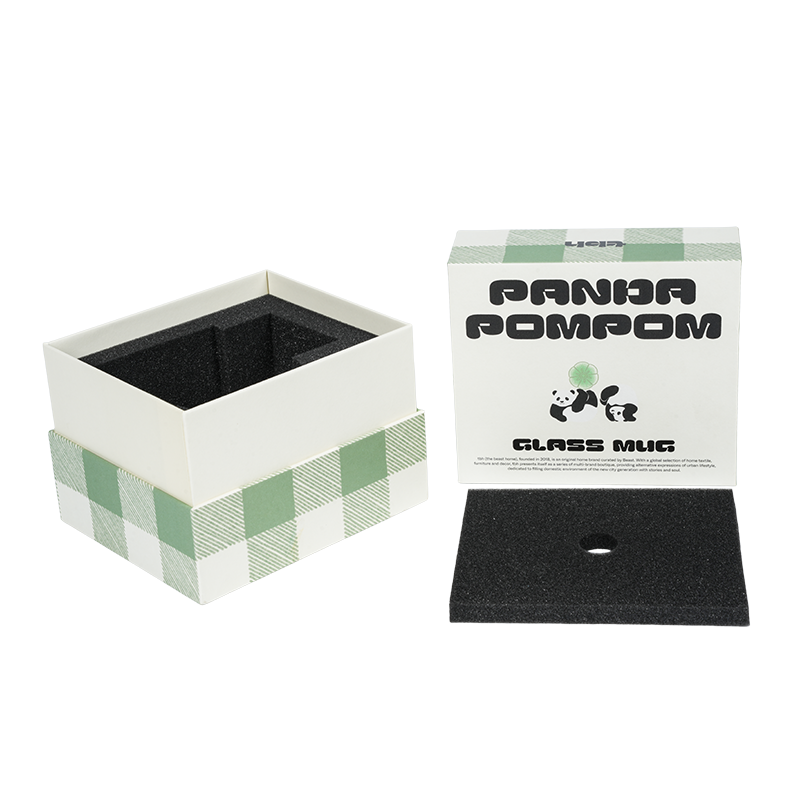

General gift packaging boxes serve a broad range of products, making internal customization critical for both protection and presentation. A well-designed interior ensures items remain secure during shipping and storage, while also enhancing the unboxing experience. By incorporating dividers, inserts, and padding, these boxes adapt to diverse product shapes, sizes, and fragility levels, offering versatility that mass-produced, standard boxes alone cannot achieve.

Types of Customizable Dividers and Inserts

Customizable dividers and inserts provide tailored protection for individual items within a box. They prevent movement, reduce impact damage, and create a professional, organized presentation. The choice of material and design depends on the product’s weight, shape, and fragility.

Common Divider Options

- Cardboard partitions: Simple, cost-effective dividers suitable for lightweight items.

- Foam cutouts: Molded to fit specific product shapes, offering cushioning for delicate objects.

- Adjustable plastic dividers: Reusable and flexible for varying product sizes.

- Corrugated inserts: Provide extra strength for heavier items while keeping them separated.

Types of Protective Inserts

- Die-cut foam: Precisely cut to cradle fragile or irregularly shaped items.

- Velvet or satin lining: Adds a premium feel while preventing scratches and abrasions.

- Shredded paper or crinkle paper: Lightweight, eco-friendly cushioning for multiple small items.

- Air cushions and bubble trays: Provide shock absorption for high-value or delicate goods.

Material Selection for Interiors

Choosing the right material for dividers and inserts ensures adequate protection while aligning with environmental and aesthetic considerations. Common options include foam, cardboard, corrugated sheets, plastic, and textile linings. Materials should be selected based on factors such as product weight, fragility, moisture resistance, and visual appeal. Using recyclable or biodegradable materials supports sustainability, which is increasingly valued by both businesses and consumers.

Comparison of Interior Materials

| Material | Protection Level | Aesthetic Appeal | Eco-Friendliness |

| Foam | High | Moderate | Varies (some recyclable) |

| Cardboard | Medium | Low | High |

| Velvet/Satin | Medium | High | Low |

| Plastic Inserts | High | Moderate | Low |

Benefits of Customizable Interiors

Customizable interiors provide multiple advantages beyond simple protection. They improve the presentation of products, ensuring a premium look even for standard packaging boxes. By keeping items securely in place, they reduce damage rates and product returns, which lowers operational costs. Additionally, adaptable interiors allow businesses to use a single packaging style for a wide variety of products, streamlining inventory and production processes.

Key Advantages

- Enhanced product protection during transit and storage

- Improved unboxing experience, reinforcing brand perception

- Reduced returns and damage-related costs

- Flexibility to accommodate different product sizes and shapes

- Supports sustainable practices with recyclable or biodegradable materials

Design Considerations for Businesses

When designing customizable interiors, businesses must consider product fragility, box size, and shipping conditions. Precise measurements for inserts prevent movement and impact damage, while thoughtful material selection balances protection, cost, and aesthetics. Collaboration with packaging manufacturers ensures that production processes, such as die-cutting, laminating, or gluing, are optimized for both quality and scalability.

Ultimately, investing in customizable interiors transforms general gift packaging boxes from simple containers into multifunctional solutions that protect products, enhance customer experience, and support operational efficiency.