Production Capacity Guarantee – Large-Scale Production

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Cosmetic Packaging Boxes Manufacturers and OEM Cosmetic Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

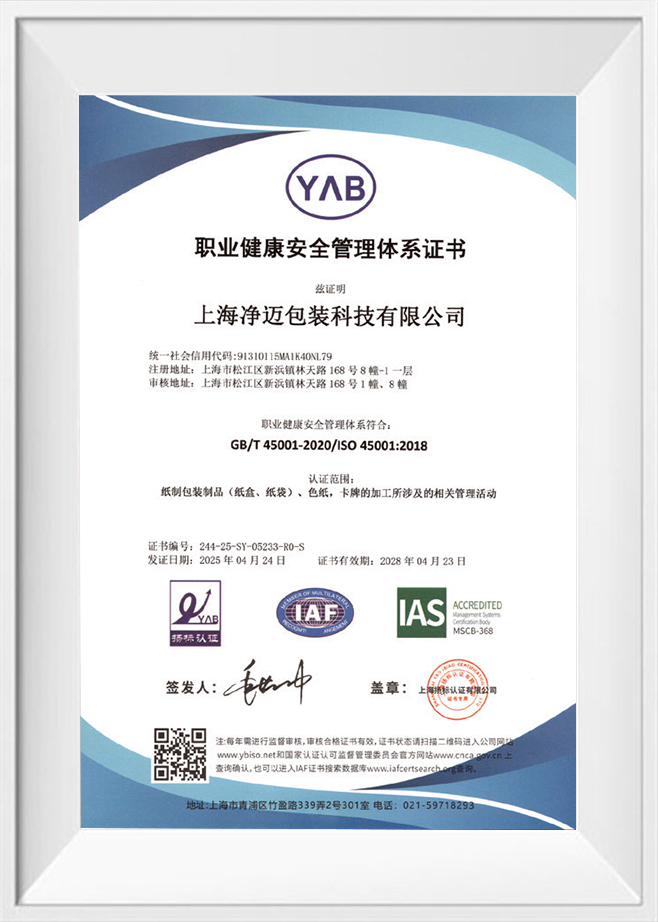

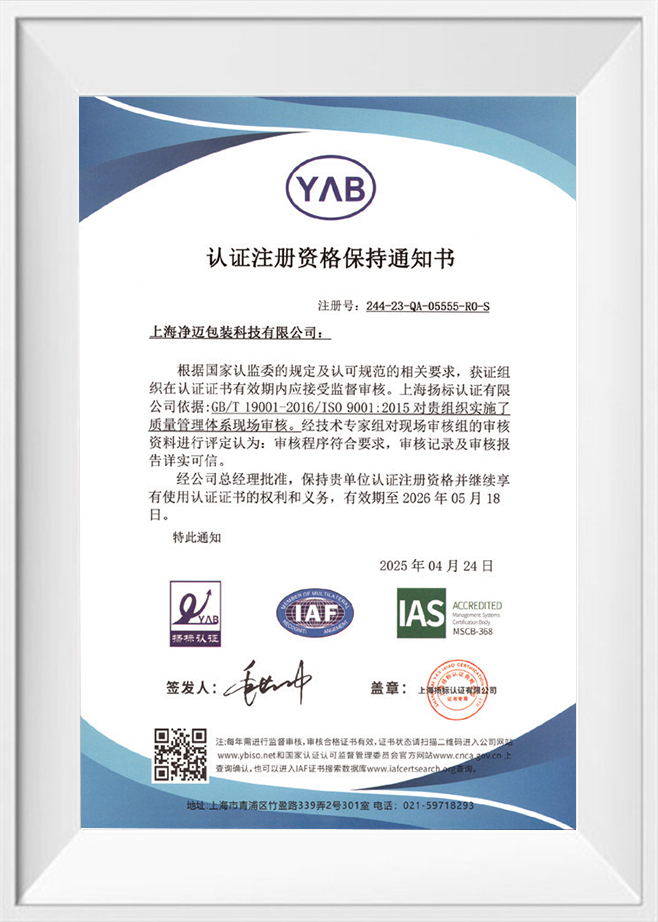

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

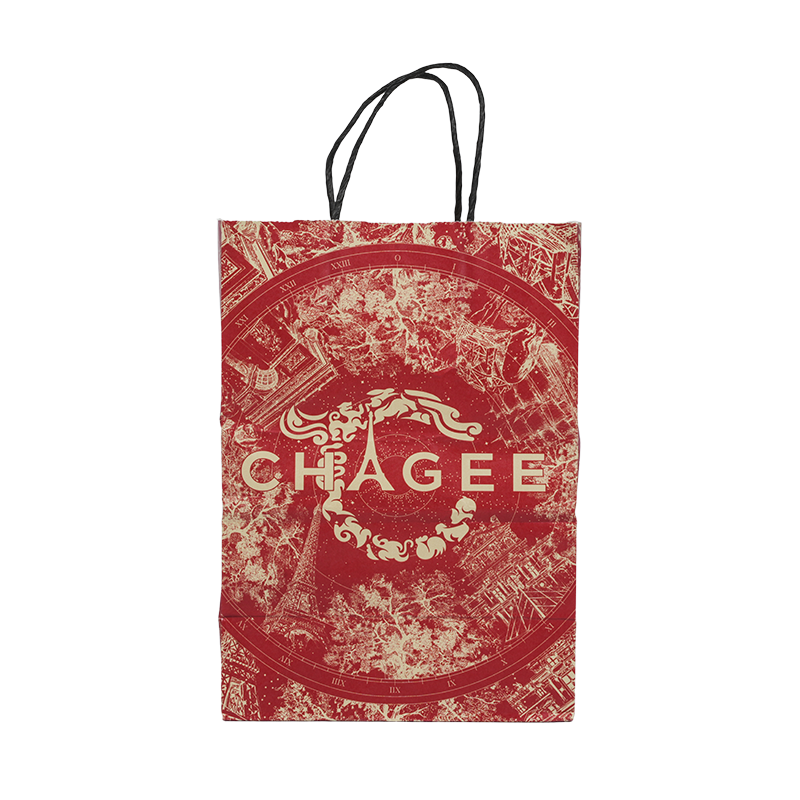

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Cosmetic Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Cosmetic Packaging Boxes Manufacturers

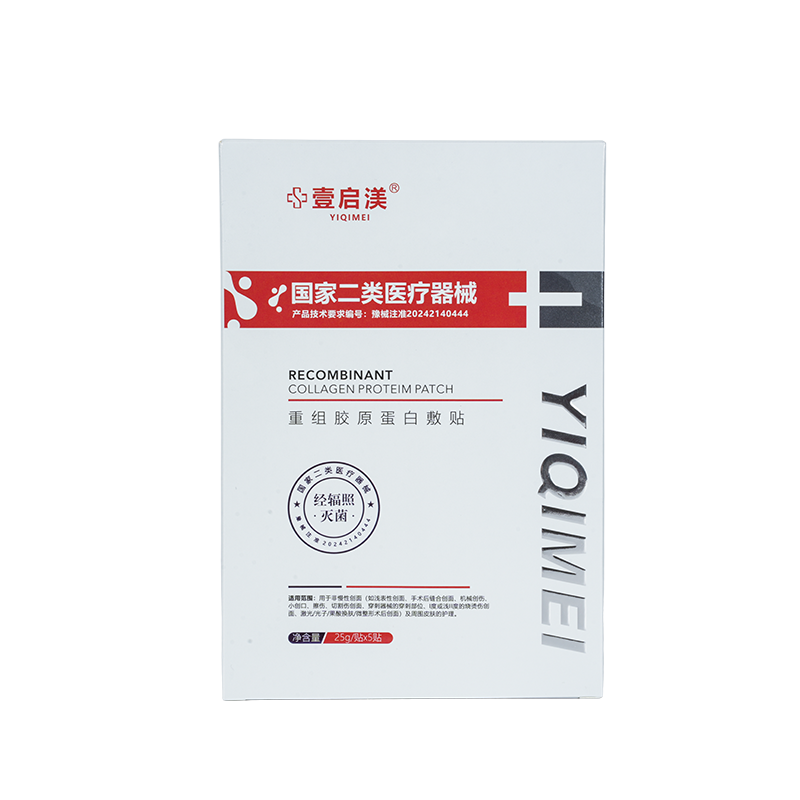

Cosmetic packaging boxes are designed to balance product protection, user convenience, and brand value expression, while also adapting to different consumer scenarios.

Core Protective Functions

Cosmetic packaging shields the product from environmental exposure by blocking light, oxygen, moisture, and dust, helping prevent oxidation, deterioration, or contamination of cosmetic ingredients.

Its physical protection provides cushioning against impact or compression during transportation or daily carrying, especially for glass-bottled or fragile items.

A well-designed sealing structure preserves product activity, extends shelf life, and reduces issues such as leakage or seepage.

Enhancing Use and User Experience

Structured packaging designs improve accessibility. Layered boxes or built-in compartments allow organized storage of multi-shade items such as eyeshadow or blush, preventing product mixing.

Portable packaging formats meet on-the-go needs; compact boxes allow users to carry makeup for touch-ups, and sealed cases keep powder products from spilling.

Additional functional features, such as built-in mirrors, brush slots, or magnetic closures, enhance convenience and practicality.

Communicating Brand and Marketing Value

The appearance of a cosmetic box acts as a brand’s visual identity. Material selection, color tone, logo design, and finishing techniques communicate brand positioning, whether premium, minimalistic, or luxurious.

Clear printed information presents ingredients, benefits, usage instructions, and shelf life in an intuitive format to help consumers understand the product.

Attractive, refined packaging elevates product perception, encourages purchase decisions, and also supports gifting scenarios.

Compliance and Safety Assurance

Cosmetic packaging must meet industry standards by displaying batch numbers, origin, and regulatory records to support compliant sales.

Some packaging features anti-counterfeiting elements such as QR codes or holographic labels, helping consumers verify authenticity and reduce the risk of counterfeit products.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Material Selection for Cosmetic Packaging Boxes

Material selection is one of the most critical aspects in cosmetic packaging design. Paperboard, coated boards, and specialty art boards are commonly used to create both structural strength and visual appeal. High-quality cosmetic boxes must be rigid enough to protect delicate products such as perfumes, creams, or makeup while allowing for detailed printing and finishing. Coated surfaces and lamination provide additional durability, resistance to moisture, and a premium tactile experience for consumers.

Environmental concerns are increasingly influencing material choices. Recyclable and eco-friendly boards can deliver an upscale look while meeting sustainability goals, which is particularly important for beauty brands emphasizing ethical production.

- Paperboard: strong, printable, suitable for a variety of cosmetic products.

- Coated boards: provide smooth surfaces for detailed graphics and text.

- Specialty art boards: ideal for premium packaging with unique textures.

- Eco-friendly options: recyclable and sustainable for environmentally-conscious brands.

Design and Structural Innovations

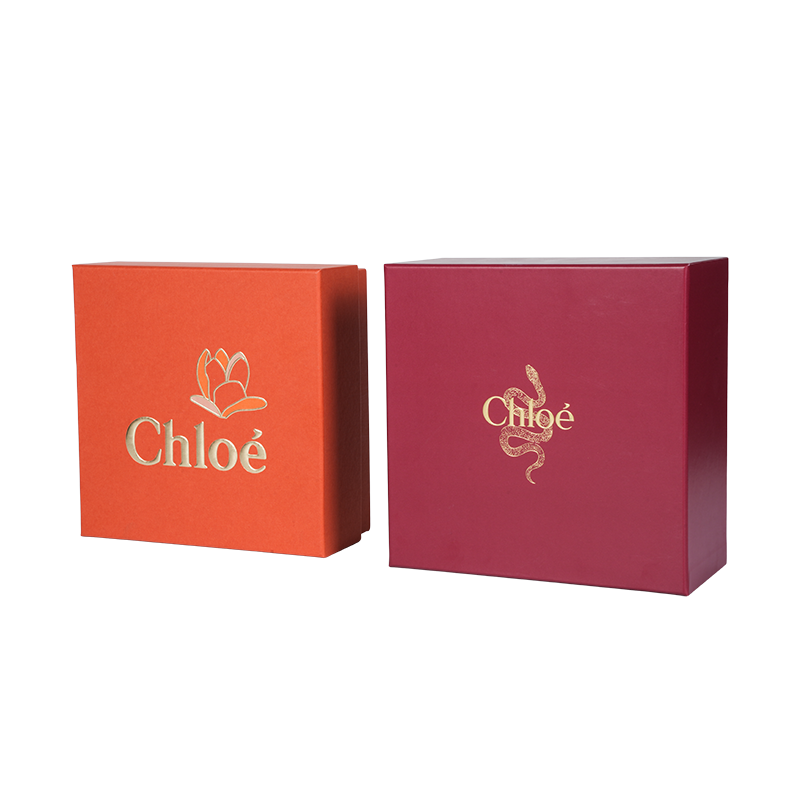

Cosmetic packaging must balance function, aesthetics, and brand identity. Structural design varies from simple tian di gai boxes to luxurious drawer-style or book-style boxes, which offer an elevated unboxing experience. Reinforced edges, interlocking flaps, and magnetic closures enhance both durability and consumer engagement. Window cutouts can showcase the product inside while protecting it, and internal compartments or foam inserts prevent damage during shipping.

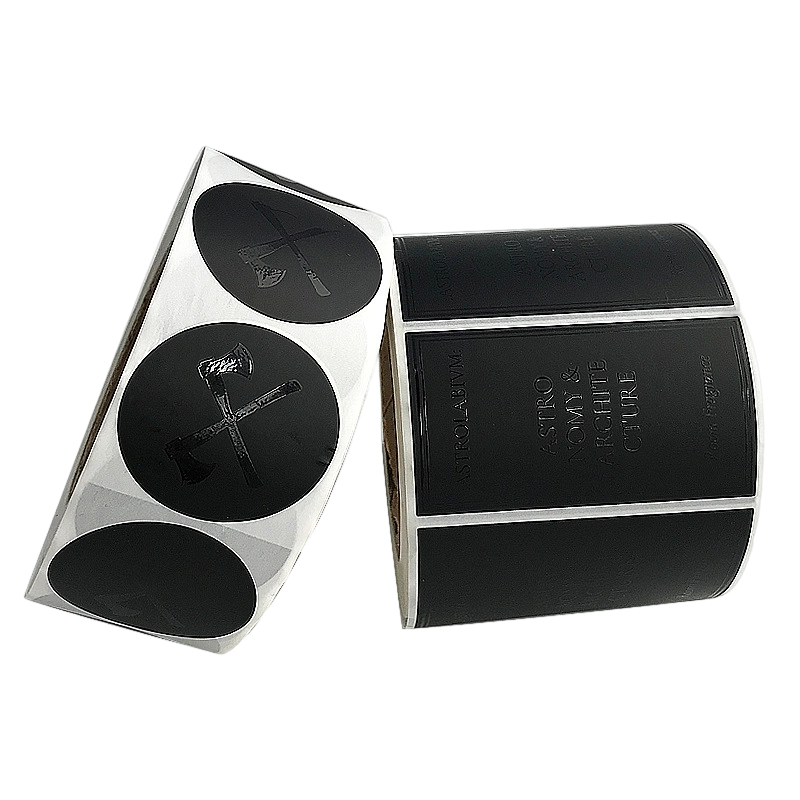

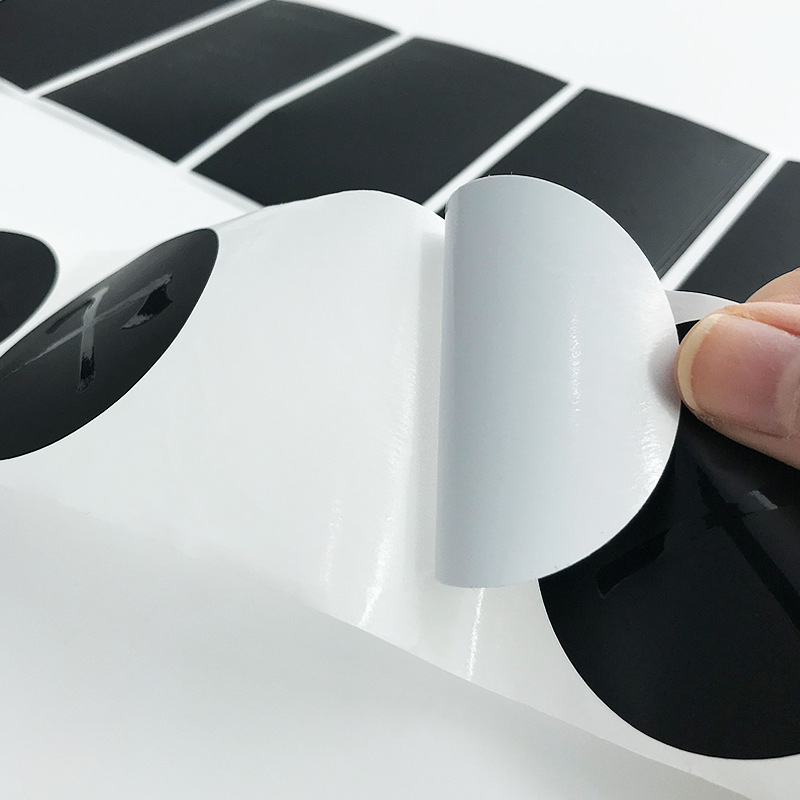

Advanced printing techniques, such as foil stamping, embossing, and UV coating, elevate visual appeal and create a premium tactile impression. Consistency across multiple packaging units is essential to maintain brand perception.

- Drawer boxes and book-style boxes for premium cosmetic lines.

- Windowed boxes for product visibility without compromising protection.

- Reinforced edges and magnetic closures for structural integrity.

- Embossing, hot stamping, and lamination for high-end finishes.

Production Technologies for Consistency and Quality

Advanced manufacturing equipment ensures consistent quality in cosmetic packaging. Automatic die-cutting machines provide precise folds and shapes, while box-making machines ensure structural accuracy at scale. Film lamination, hot stamping, and UV coating improve surface durability, color retention, and resistance to fingerprints or minor scratches. Maintaining strict quality control at every stage—from paper mounting to gluing—is essential to deliver premium cosmetic packaging that meets brand standards.

ISO9001-certified processes ensure that every batch of cosmetic boxes complies with safety and quality standards, which is critical for products that may come into contact with sensitive skin or cosmetics formulations.

- Automatic die-cutting for precise shapes and folds.

- Film lamination and UV coating for surface protection and aesthetics.

- Box-making machines for structural uniformity and efficiency.

- ISO9001 quality control to maintain consistent production standards.

Customization and Branding Advantages

Cosmetic packaging boxes serve as a critical marketing tool, reflecting brand identity and attracting consumers. One-stop packaging solutions allow for full customization, from size and shape to color, graphics, and finishes. Drawer boxes with embossed logos, metallic foiling, or soft-touch coatings create a memorable unboxing experience, which can increase customer loyalty and perceived value.

Custom inserts can safely secure products such as bottles, jars, or compact makeup while enhancing presentation. Integration of seasonal or limited-edition designs further enables brands to differentiate their products in competitive markets.

- Full customization of size, shape, and surface finish.

- Foil stamping, embossing, and UV coating for brand differentiation.

- Internal inserts for product security and enhanced presentation.

- Limited-edition or seasonal designs to attract consumer attention.

Sustainability in Cosmetic Packaging

Sustainable packaging is increasingly demanded in the cosmetics industry. Using recycled paperboards, eco-friendly inks, and laminates reduces environmental impact while maintaining structural integrity and visual quality. Manufacturers can optimize production lines to reduce material waste and energy consumption, supporting eco-conscious branding strategies.

For cosmetic brands, sustainable packaging not only satisfies regulatory requirements but also enhances consumer trust and strengthens brand reputation in a market increasingly attentive to environmental responsibility.

- Recycled paperboards and sustainable laminates reduce environmental impact.

- Eco-friendly inks and coatings minimize chemical hazards.

- Production optimization reduces waste and energy usage.

- Supports brand messaging on sustainability and social responsibility.

Comparing Cosmetic Box Types for Different Products

Choosing the right box type depends on product fragility, presentation needs, and brand positioning. A comparative overview can help guide selection:

| Box Type | Best For | Key Features |

|---|---|---|

| Tian Di Gai Box | Single products like perfume bottles or small creams | Quick assembly, sturdy, printable surface for branding |

| Drawer Box | Luxury or multi-piece cosmetic sets | Sliding mechanism, premium look, reusable |

| Book-style Box | Makeup palettes or limited-edition cosmetic collections | High-end presentation, magnetic closure, compartment inserts |

Proper selection of cosmetic packaging boxes ensures product safety, enhances consumer experience, and strengthens brand recognition in a competitive market.