Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion...

Read MoreStain-resistant push-fit cardboard perfume box

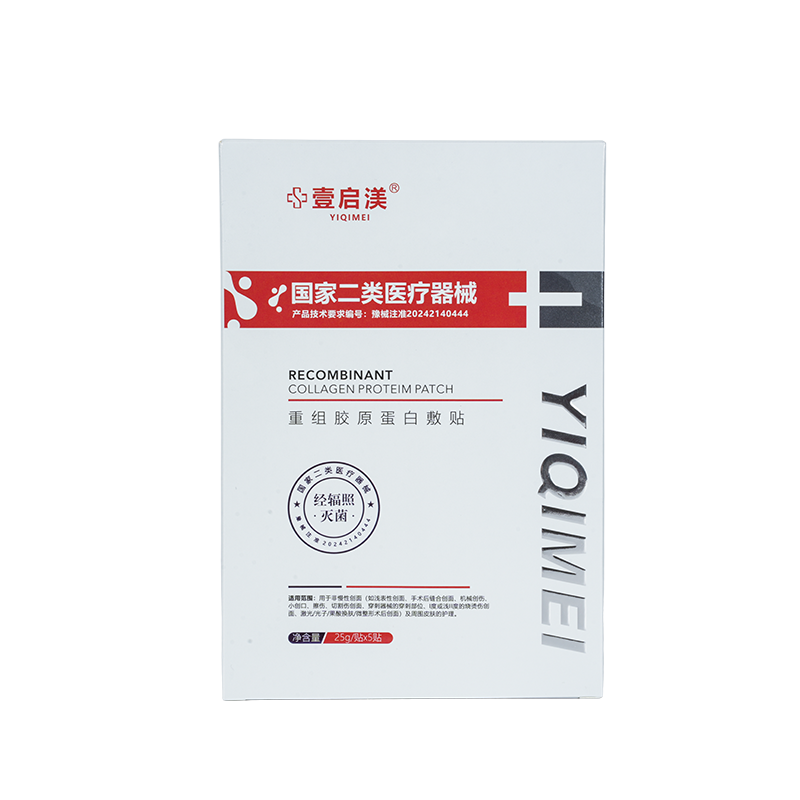

Product DESC

The core advantages of cardboard boxes for perfume packaging are lightweight protection, strong brand expression, and high cost-performance—while adapting well to distribution and display scenarios. It is the preferred packaging solution for entry-level and sample-size perfumes.

1. Lightweight Protection – Safeguarding the Perfume Bottle

● Self-supporting structure provides moderate cushioning against minor impacts during transport and handling—preventing scratches or minor damage to glass bottles, and protecting both bottle body and spray nozzle integrity.

● Custom inserts, retention slots, or buffer structures can be designed to securely hold the perfume bottle in place—preventing movement or displacement during transit—especially suitable for small-capacity or portable formats.

● Light and thin material adds negligible weight or volume—reducing logistics and shipping costs, avoiding over-packaging, and aligning with the lightweight trend.

2. Branding & Aesthetic Appeal – Conveying Fragrance Identity

● High print adaptability: supports full-color printing, hot foil stamping, UV coating, and embossing—enabling clear presentation of brand logo, thematic visuals, and fragrance notes to strengthen brand recognition.

● Flexible material selection: coated paper or specialty papers create minimalist-modern or refined light-luxury aesthetics—well-matched to diverse fragrance profiles (e.g., fresh, rich, niche)—enhancing product perceived quality.

● Varied structural designs: available with die-cut windows, pull-out trays, or foldable formats—window panels showcase bottle design directly; pull-out mechanisms elevate unboxing ritual—adding refinement even to entry-level offerings.

3. Practical Adaptability – Covering Diverse Scenarios

● Highly customizable sizing: accommodates sample sizes (1–10ml), travel sizes (15–30ml), and standard sizes (50ml)—ideally suited for perfume samples, trial sets, and introductory editions.

● Excellent shelf presence: uniform shape allows neat stacking in boutiques or beauty stores—space-efficient and visually organized, improving display efficiency.

● High portability: lightweight design enables easy consumer carrying (e.g., for travel or touch-ups); also functions well as a souvenir gift or promotional giveaway—no secondary packaging needed.

4. Cost Efficiency & Eco-Friendliness – Balancing Value and Trends

● Low production cost: raw materials are readily available and manufacturing processes mature; bulk unit price is significantly lower than rigid gift boxes—aligning with pricing strategies for samples and entry-level products, reducing merchant expenses.

● Eco-friendly and easy to dispose: made from recycled or biodegradable paper, printed with water-based inks—fully recyclable and compostable—imposing no environmental burden, in line with green consumption trends.

● Efficient storage and logistics: boxes can be shipped and stored flat—minimizing warehousing space; stackable when assembled—greatly improving transport efficiency.

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. Stain-resistant push-fit cardboard perfume box Suppliers in China. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

-

-

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked asp...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negat...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail e...

Read More -

Introduction to Home Textile Packaging Home textile packaging plays a crucial role in the modern retail and logistics ecosystem. Beyond simply protecting products like bed linens, curtains, and cushio...

Read More