Production Capacity Guarantee – Large-Scale Production

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Chocolate Packaging Boxes Manufacturers and OEM Chocolate Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

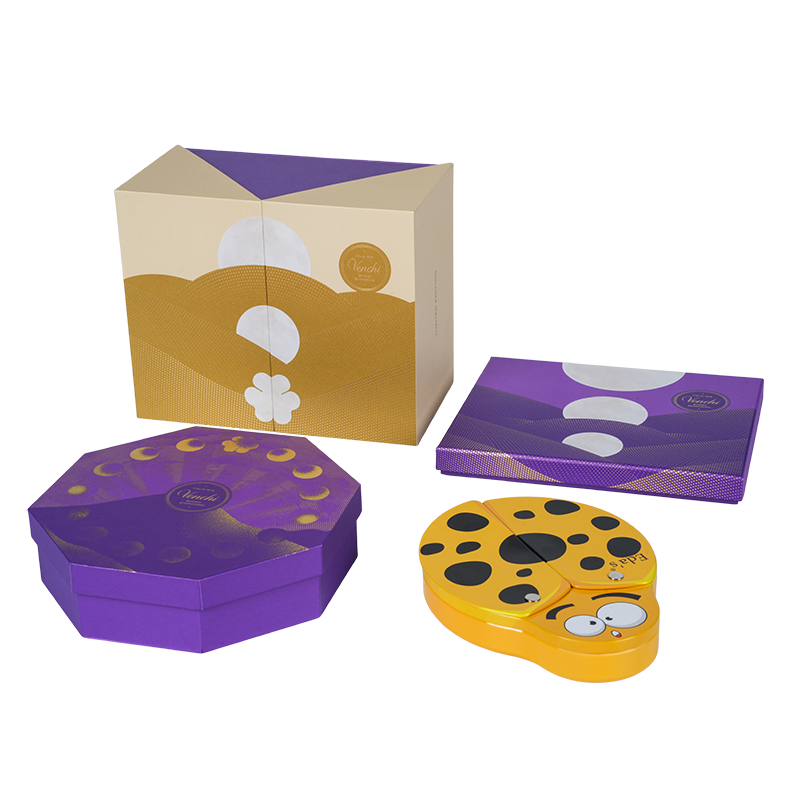

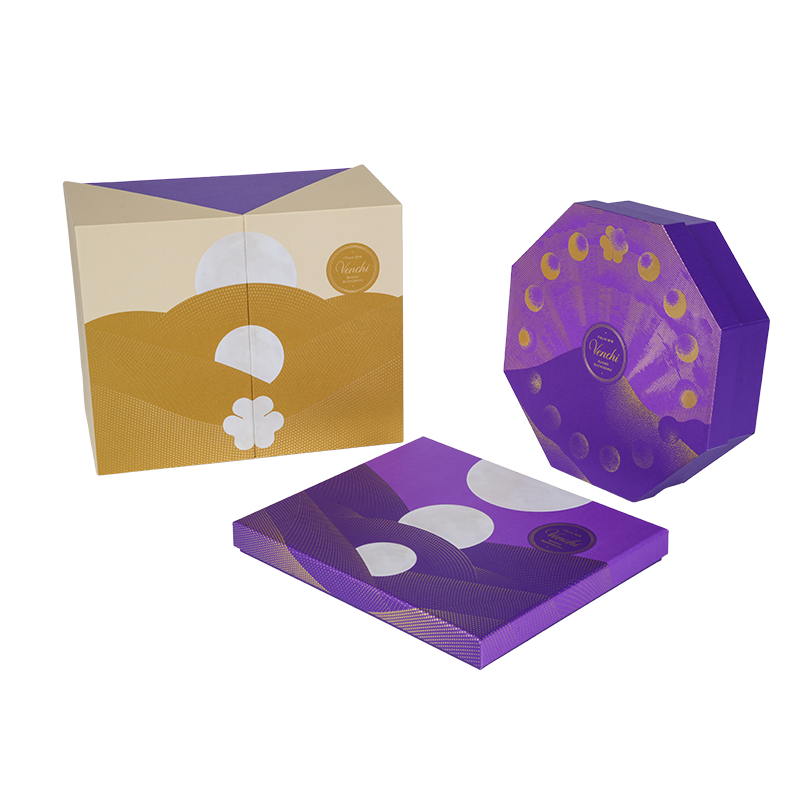

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Chocolate Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Chocolate Packaging Boxes Manufacturers

Designed to tackle chocolate’s vulnerabilities—melting, moisture sensitivity, and aroma loss—our packaging ensures quality integrity across storage, gifting, and retail.

1. Core Protection: Preserve Texture, Flavor & Appearance

Moisture & Temperature Control: High-barrier materials (aluminum-laminated film, sealed tin cans) prevent humidity uptake—eliminating sugar bloom and softening.

Oxygen Barrier for Aroma Retention: Multi-layer films block oxidation, preserving cocoa butter richness and extending flavor shelf life.

Light & Heat Shielding: Opaque or dark-colored packaging (e.g. matte paperboard, metal tins) with optional thermal liners minimizes UV exposure and heat-induced deformation.

Hygienic & Damage-Resistant: Individual wrapping + rigid outer boxes prevent crushing and contamination—ensuring cleanliness from production to consumption.

2. Scenario-Adaptive Solutions

Smart Storage: Resealable tins, zipper pouches, and single-portion wraps (e.g. foil-wrapped pieces) enable portion control and freshness retention after opening.

Gift-Ready Elegance: Luxury gift boxes with foil stamping, embossing, ribbon accents, and compartmentalized trays—ideal for Valentine’s Day, birthdays, and holidays.

Flexible Formats: Pocket-sized bars or mini boxes for on-the-go; large sharing sets for family or corporate gifting; retail-ready packs for shelf appeal and impulse buys.

3. Compliance & Brand Elevation

Regulatory Compliant: Dedicated labeling area for cocoa %, ingredients, allergens (nuts, dairy), production/best-before dates—meeting global food safety standards.

Premium Positioning: Metallic, wooden, or textured rigid boxes with refined printing justify premium pricing and distinguish artisanal/fine chocolate lines.

Brand Recognition: Signature design elements—distinct color palettes (e.g., black-gold for luxury, pastel tones for romance), custom shapes, and logo integration—enhance shelf impact and recall.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Temperature Sensitivity and Structural Protection Logic

Chocolate packaging boxes must account for the product’s sensitivity to temperature and pressure. Although temperature control mainly depends on logistics, box structure plays a supporting role by protecting inner trays and preventing deformation that can lead to surface blooming or cracking. Rigid box walls with stable corner support help maintain internal spacing, reducing pressure transfer when boxes are stacked. In our production experience, optimizing structure often proves more effective than simply increasing material thickness.

This is especially relevant for gift chocolate boxes that undergo repeated handling before reaching end consumers.

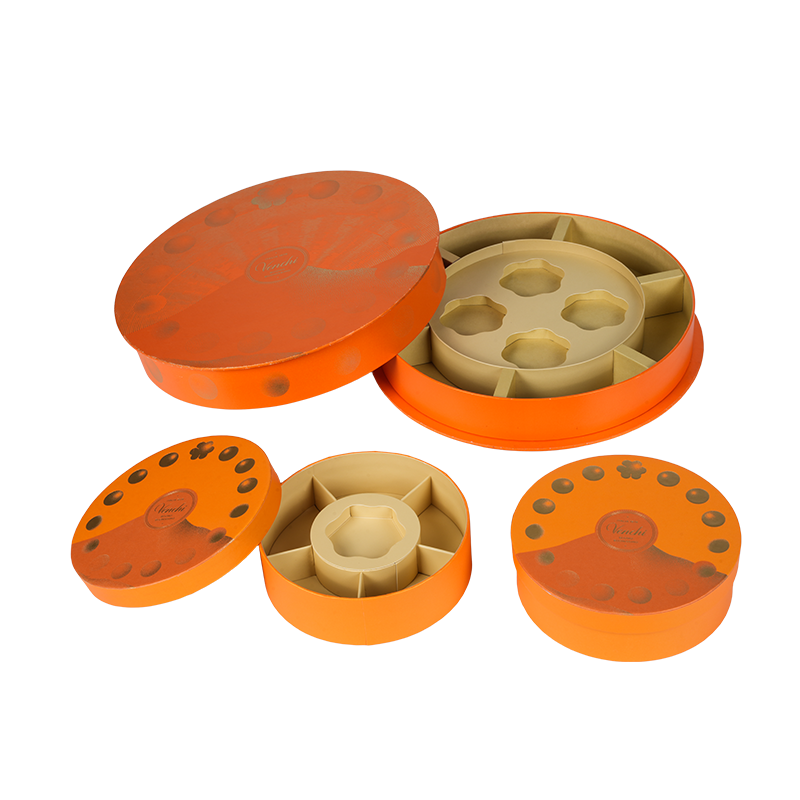

Internal Tray Design for Shape and Finish Preservation

Internal trays are critical components of chocolate packaging boxes, as they directly influence product appearance upon opening. Paper-based trays with precise cavities help prevent chocolates from shifting or rubbing against each other. Compared with plastic trays, paper solutions require tighter die-cut accuracy to achieve the same positioning effect. With automatic die-cutting and mounting equipment, we can maintain consistent cavity dimensions across large OEM runs.

- Individual cavities reduce surface abrasion on glossy chocolates.

- Shallow-depth trays support filled or soft-center chocolates.

- Reinforced tray edges improve load stability during transport.

Surface Finishing and Smudge Resistance

Chocolate packaging boxes often use dark colors, metallic elements, or matte finishes to convey a premium image. These design choices increase sensitivity to fingerprints, scuffs, and dust. Practical surface treatments focus on balancing visual effect with durability. Matte lamination and soft-touch films are commonly selected, but they require controlled pressure and temperature during application to avoid marks or uneven texture. In our clean workshop environment, controlled conditions help maintain consistent surface quality.

Commonly Used Surface Treatments

- Matte lamination for reduced glare and refined appearance.

- Soft-touch film to enhance tactile perception.

- Hot stamping for logos without heavy ink coverage.

Automation Compatibility for Seasonal Demand

Chocolate packaging boxes often face sharp seasonal peaks during holidays. To handle these fluctuations, box designs must align with automated production processes. Structures compatible with automatic box-making and gluing machines reduce reliance on manual labor and improve delivery reliability. With a 13,000-square-meter production base and multiple automated lines, we prioritize designs that maintain stable output even under tight schedules.

| Design Aspect | Manufacturing Result | Brand Benefit |

| Pre-glued Box Structure | Higher efficiency | On-time seasonal supply |

| Standardized Tray Design | Stable batch quality | Consistent unboxing experience |

Quality Control Focus in Clean Workshop Production

Quality control for chocolate packaging boxes emphasizes cleanliness, dimensional accuracy, and surface consistency. Dust particles, glue marks, or minor scratches are highly visible on dark or matte finishes. Operating under an ISO9001 quality management system, we monitor key process points such as die-cut alignment, adhesive application, and lamination stability. From our perspective, combining automated equipment with experienced operators is essential for maintaining quality across large-scale OEM orders.

This process-oriented approach supports reliable long-term cooperation with chocolate brands that demand both visual precision and production stability.