Production Capacity Guarantee – Large-Scale Production

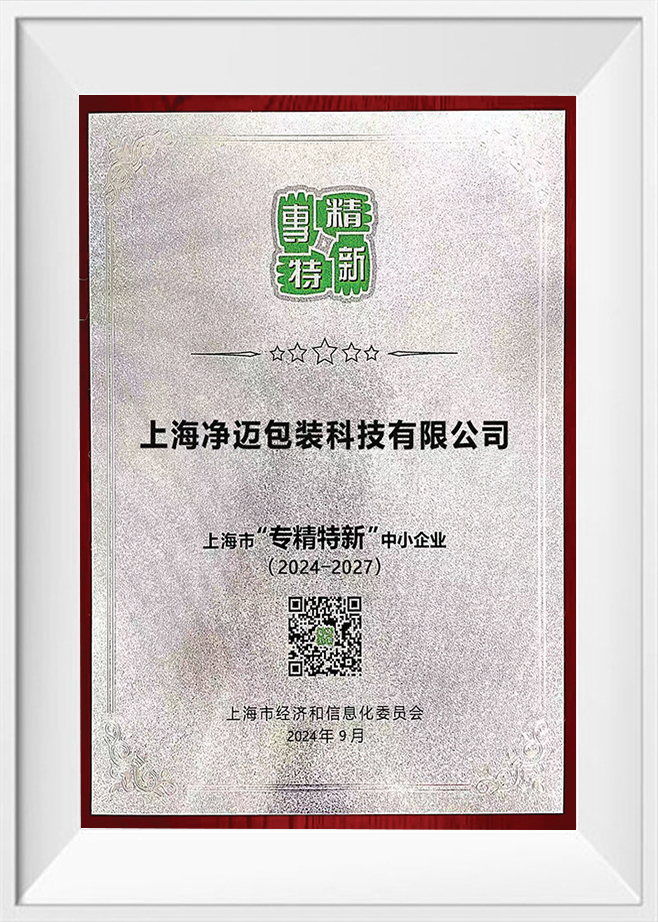

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Health Supplement Packaging Boxes Manufacturers and OEM Health Supplement Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

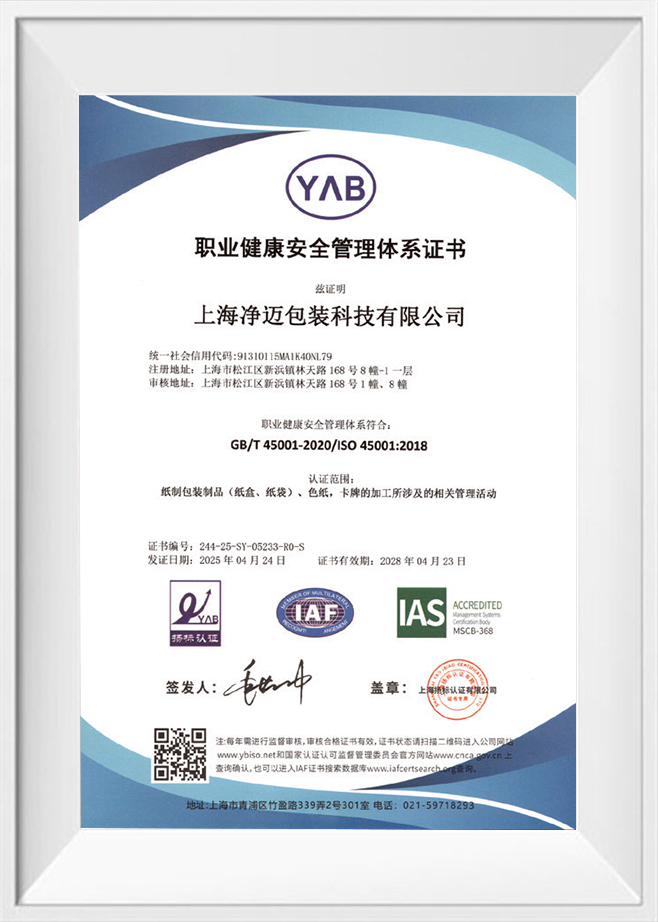

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

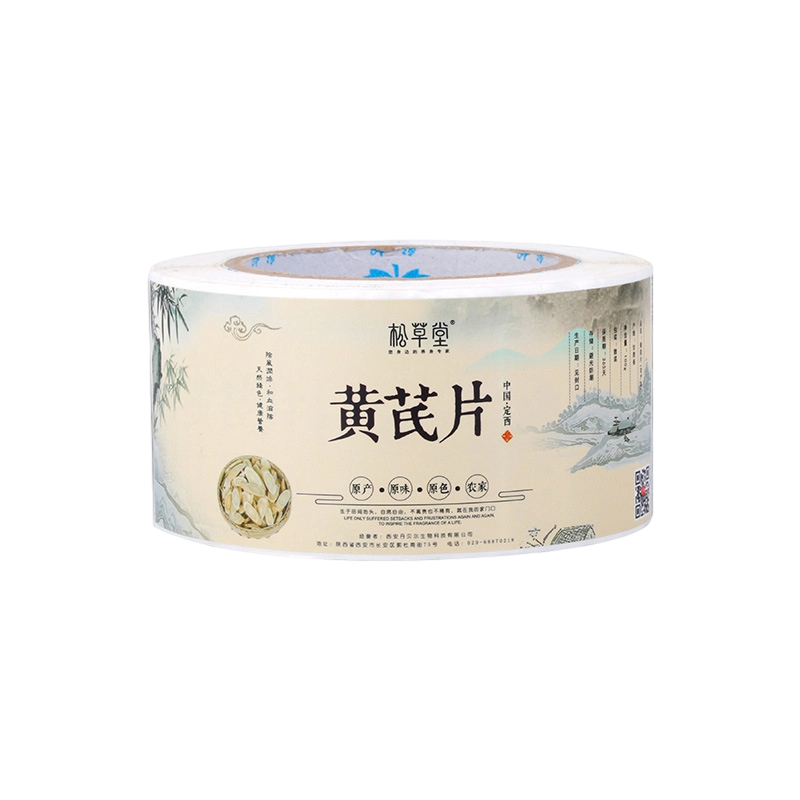

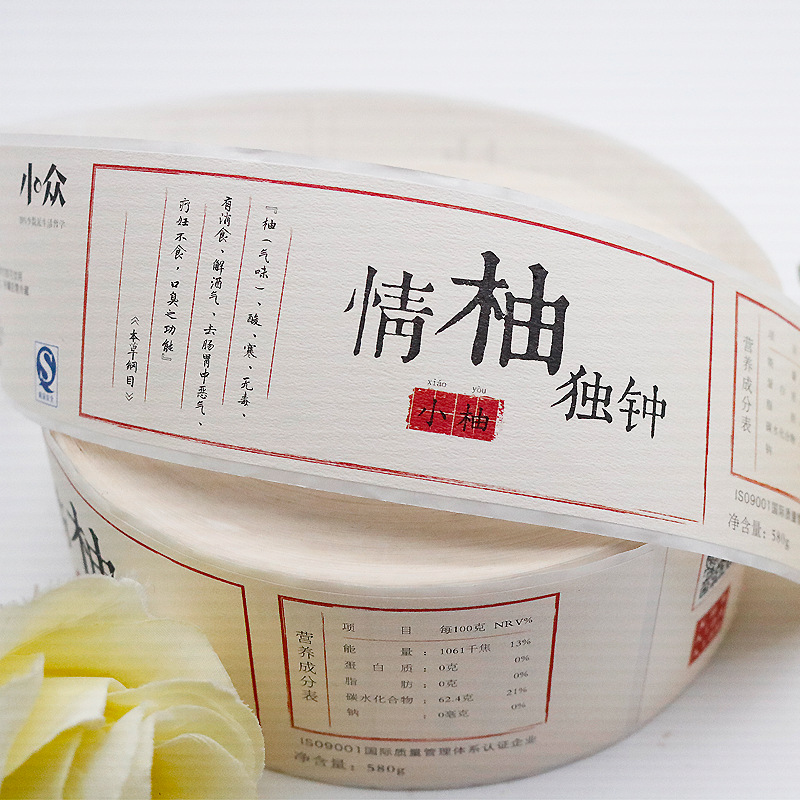

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Health Supplement Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Health Supplement Packaging Boxes Manufacturers

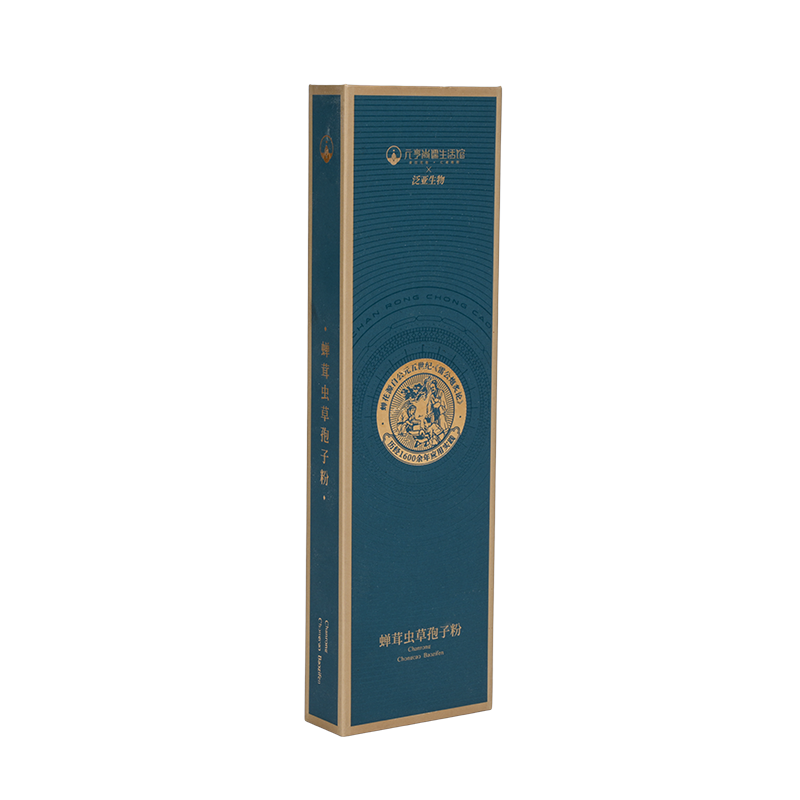

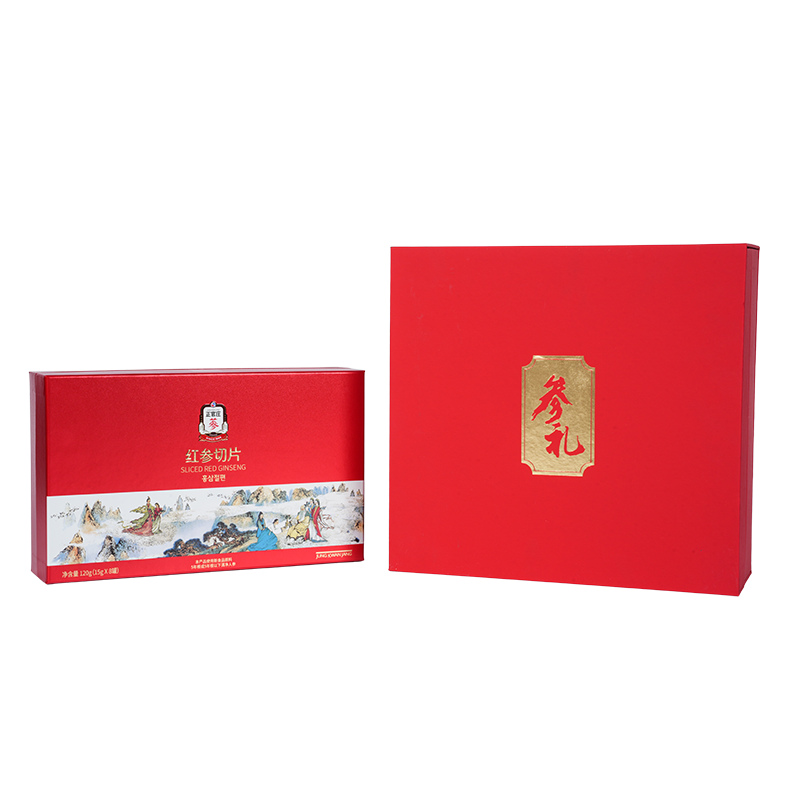

Designed for high-value tonics and traditional remedies—where potency, integrity, and perceived worth must be preserved from warehouse to recipient.

1. Dual-Stage Protection: Safeguard Efficacy & Integrity

Enhanced Freshness & Moisture Control: Outer rigid box + inner high-barrier liners (aluminum foil pouches, vacuum-sealed bags) with dedicated desiccant compartments—prevents mold, clumping, and oxidation in hygroscopic items (e.g., bird’s nest, dried goji, cordyceps).

Shock & Crush Resistance: Premium materials (solid wood, metal tins, rigid paperboard) with custom-fit cushioning (velvet, EPE foam, molded pulp inserts) securely hold fragile forms—critical for intact ginseng roots, whole cordyceps, or glass vials.

Light & Odor Isolation: Fully opaque, UV-blocking construction preserves light-sensitive actives (e.g., polysaccharides, saponins); odor-neutral materials prevent flavor/fragrance contamination—ensuring authentic taste and therapeutic value.

2. Elevated Gifting & Usability

Luxury Unboxing Experience: Custom finishes—foil stamping, embossing, silk-screened motifs, satin ribbon, or embroidered inserts—plus optional transparent windows to showcase premium contents. Ideal for corporate gifting, Lunar New Year, elder-care, or wellness occasions.

Functional Storage: Elegant boxes double as long-term storage—stackable, dust-proof, and often multi-tiered for organizing different SKUs (e.g., daily doses vs. bulk reserves). Fits seamlessly in home cabinets or display shelves.

Logistics-Reliable: Standardized dimensions with impact-absorbing structure ensure safe long-distance shipping—minimizing breakage and leakage for high-value cross-border e-commerce.

3. Value Communication & Trust Building

Premium Positioning: Wooden chests, lacquered metal tins, or artisanal paper boxes signal rarity and craftsmanship—justifying premium pricing and distinguishing from commoditized supplements.

Transparent Storytelling: Ample space for origin traceability (e.g., Tibetan cordyceps, Jilin ginseng), processing methods (sun-dried, low-temp extraction), third-party lab reports, and usage guidance—building authenticity and confidence.

Brand Authority: Cohesive design language—color coding (gold for heritage, jade green for purity), signature patterns (e.g., traditional motifs), and embossed logos—creates instant recognition and emotional resonance.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Why High-Barrier Inner Packaging Is a Non-Negotiable for Hygroscopic Supplements

For hygroscopic ingredients such as bird’s nest, dried goji, or cordyceps, moisture ingress is not a minor defect—it directly compromises efficacy, shelf life, and resale value. High-barrier inner packaging (aluminum foil pouches, vacuum-sealed bags) functions as the first line of defense, while the outer rigid box provides structural protection and brand presentation.

In bulk distribution scenarios, especially where storage conditions vary by region, relying on a single-layer paper solution significantly increases risk. We consistently recommend a dual-stage system because controlling water vapor transmission rate (WVTR) at the inner layer reduces spoilage risk by orders of magnitude.

- Aluminum foil laminates block oxygen and moisture simultaneously

- Dedicated desiccant compartments prevent direct contact contamination

- Vacuum sealing minimizes oxidation during long-haul transport

Structural Design Considerations for Fragile, Irregular Raw Materials

Whole ginseng roots, intact cordyceps clusters, and glass tonic vials present a challenge that standard carton inserts cannot solve. The issue is not just cushioning, but positional stability—preventing micro-movements that cause abrasion or fracture over time.

From our production experience of Health Supplement Packaging Boxes, custom-fit internal structures reduce transit damage rates by more than 60% compared to generic fillers. This becomes especially relevant for bulk buyers shipping across multiple distribution layers.

| Insert Material | Shock Absorption | Suitability for Irregular Shapes |

|---|---|---|

| Velvet-lined trays | Medium | High |

| EPE foam | High | Medium |

| Molded pulp | Medium | Low |

Light, Odor, and Material Interference: Hidden Risks in Supplement Packaging

Many active compounds found in traditional remedies—such as polysaccharides and saponins—are light-sensitive. Prolonged exposure to UV or even strong indoor lighting can degrade potency before the product reaches the end consumer.

Equally overlooked is odor migration. Low-grade paperboard, recycled fillers, or untreated adhesives can transfer foreign smells into the product space. Once odor contamination occurs, it is irreversible, regardless of the ingredient’s intrinsic quality.

- Fully opaque structures provide consistent UV shielding

- Odor-neutral raw materials preserve authentic taste profiles

- Metal tins and laminated boards offer superior isolation

Scaling Up Without Compromising Consistency in Bulk Orders

For bulk buyers, the challenge is not just achieving a premium prototype, but replicating it at scale with minimal variance. Inconsistent die-cutting, unstable lamination, or uneven hot stamping quickly erode brand credibility when orders exceed tens of thousands of units.

Large-scale production environments with integrated printing, die-cutting, and automated box-making allow tighter process control. From our perspective, capacity and quality systems must grow together; expanding output without ISO-aligned inspection protocols is a false economy.

This is precisely why we invested early in automated lines and clean workshops—so bulk clients do not have to choose between speed and reliability.

One-Stop Packaging Integration as a Cost Control Strategy

Fragmenting design, sampling, material procurement, and production across multiple vendors often inflates hidden costs—revision delays, mismatched tolerances, and logistics inefficiencies. For complex supplement packaging, these issues compound rapidly.

A unified workflow—from structural design to final logistics—enables earlier risk identification and faster iteration. For bulk buyers, this integration frequently results in lower total landed cost, even if unit pricing appears similar.

We see packaging not as a standalone product, but as part of your supply chain infrastructure—designed to protect value, not dilute it.