Production Capacity Guarantee – Large-Scale Production

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Home Textile Packaging Boxes Manufacturers and OEM Home Textile Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

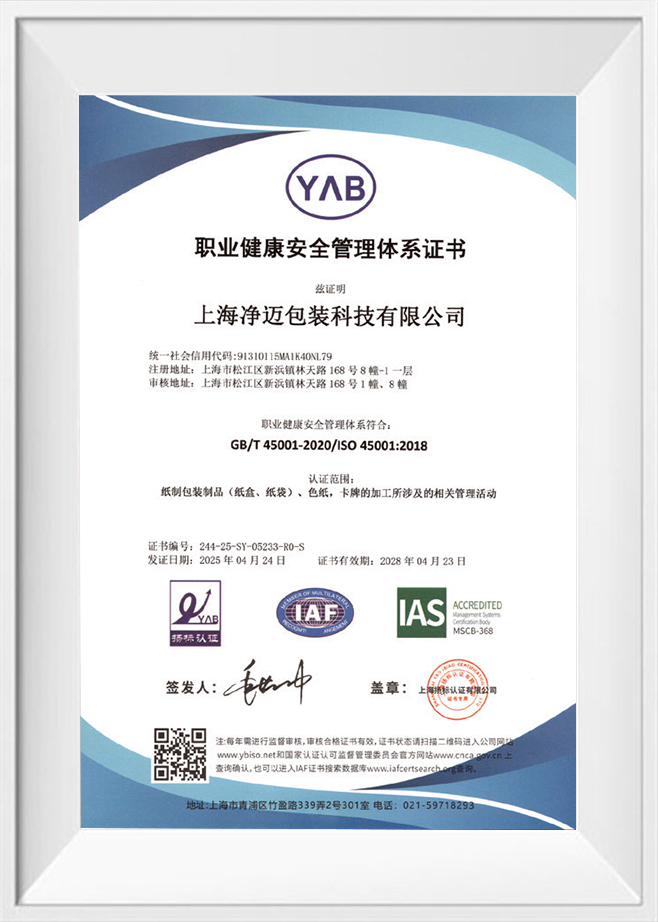

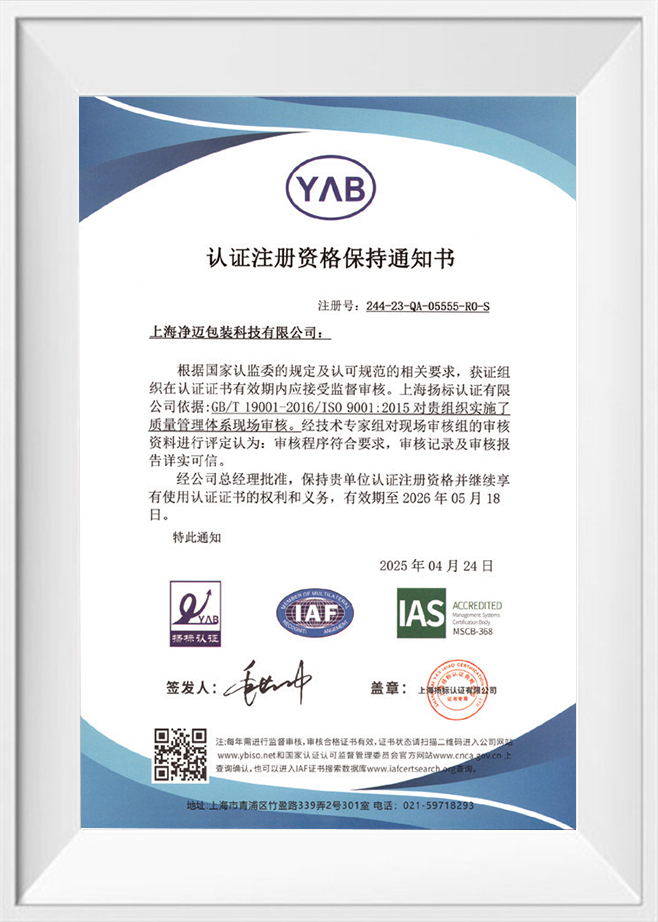

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Home Textile Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Home Textile Packaging Boxes Manufacturers

Packaging Boxes: Protection and Core Value

Designed to safeguard the characteristics of home textile products, the packaging uses moisture-resistant non-woven fabric, water-repellent coated paper boxes, and soft lining materials to block humidity and dust, preventing cotton, silk, down, and other fabrics from becoming damp, moldy, or stained. It also helps maintain the shape of bedding and curtains, reducing creases and snagging during handling.

The packaging offers strong reuse value. Zippered gift boxes and foldable storage boxes can be used as practical seasonal storage solutions. Paper boxes paired with vacuum packaging protect compressed bedding during transportation and help extend product lifespan.

The structured box design combined with hot stamping or embroidery enhances gift-giving and brand attributes. Suitable for weddings, housewarming events, and festive gifting without the need for extra wrapping. Fabric composition, size, and washing instructions are clearly marked to convey brand professionalism and increase perceived product value.

Handbags: Portability and Scenario Extension

Handbags address consumer carrying needs. Thickened non-woven bags and water-resistant paper bags with load-bearing construction support the weight of bedding sets or towel sets. Wide woven handles add convenience for post-purchase carrying and meet gift-giving needs where users prefer to “take and go”.

The printed brand logo and core selling points—such as “cotton antibacterial” or “wedding collection”—create high-frequency brand exposure. When carried outdoors, the bags act as mobile advertisements across malls, residential areas, and courier stations, expanding brand visibility.

They also provide supplementary protection. Water-repellent coatings and reinforced materials shield the inner packaging box from minor moisture or dust. Smaller handbags match towels and pillowcases, while larger reinforced options accommodate bedding sets or lightweight quilts, balancing practicality and aesthetic appeal.

The Necessity of Combining Both

A complete packaging solution covers all scenarios. The box provides protection, storage, and gifting value, while the handbag provides portability, display, and scenario extension. Together, they support the entire journey—from purchase to transportation, gifting, and long-term storage. Missing one component may break the consumer experience; for example, without a handbag, gifting becomes inconvenient, and without a box, textiles may become moist or creased.

The combination strengthens buyer decision-making. When product quality is similar, a complete “box + handbag” set reflects brand attention to detail. For weddings, housewarming events, and other gifting scenarios, this significantly influences consumers who value ceremony and presentation.

Consistent design language across both elements—color palette, logo, and craftsmanship—reinforces brand identity from inside to out. This enhances memorability, differentiates the product from competitors with minimal or no packaging, and supports higher brand value.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Material Selection Strategies for Home Textile Packaging Boxes

In home textile packaging boxes, material choice directly affects compression resistance, moisture protection, and shelf presentation. Beyond common greyboard and coated paper, many brands now combine high-density paperboard with laminated art paper to balance rigidity and print clarity. For bulky items like quilts or blankets, increasing grammage alone is not always effective; structural reinforcement through double-wall folding or edge wrapping often delivers better load-bearing performance. In our own production, we often advise optimizing structure first before upgrading material grades to control cost without sacrificing strength.

- High-density paperboard improves stacking strength during warehouse storage.

- Laminated surfaces enhance moisture resistance for long-distance logistics.

- Composite structures reduce deformation compared with single-layer solutions.

Printing Accuracy and Color Consistency Control

Home textile packaging boxes often rely on large color blocks and soft gradients to convey comfort and quality. This makes printing consistency more critical than complex graphics. Precise color management, plate calibration, and stable ink density are essential to avoid visible color shifts between batches. We rely on standardized proofing and press adjustment processes to ensure that repeated orders maintain consistent visual output, which is especially important for OEM clients managing multiple product lines.

Hot stamping and spot UV are frequently used to enhance brand logos, but excessive decorative processes can interfere with recyclability. Practical designs balance visual appeal with functional printing stability, ensuring smooth large-scale production in automated environments.

Structural Design and Assembly Efficiency

Efficient structural design in home textile packaging boxes reduces assembly time and labor costs. Box styles such as foldable rigid boxes or pre-glued structures are increasingly popular for high-volume orders. From a manufacturing perspective, designs compatible with automatic box-making machines achieve better consistency and reduce error rates. In our workshop, automated die-cutting and box forming allow us to handle complex structures while maintaining stable output.

| Structure Type | Assembly Speed | Suitable Products |

| Foldable Rigid Box | High | Blankets, Comforters |

| Drawer Box | Medium | Bedding Sets |

Quality Control Points in Large-Scale Production

When producing home textile packaging boxes at scale, quality control focuses less on individual defects and more on process stability. Key inspection points include die-cut accuracy, glue adhesion strength, and surface finish consistency. ISO9001-based quality systems emphasize traceability, enabling quick identification of deviations during mass production. From our experience, stable equipment performance and trained operators are just as important as final inspection.

- Die-cut tolerance directly affects box assembly precision.

- Glue curing time impacts long-term structural stability.

- Surface inspection prevents batch-level appearance issues.

Sustainability Considerations in Home Textile Packaging

Sustainability in home textile packaging boxes is no longer limited to recyclable materials. Practical improvements include reducing unnecessary inner trays, optimizing box size to lower shipping volume, and choosing water-based adhesives. These adjustments often improve logistics efficiency while supporting environmental goals. In our OEM projects, we frequently integrate such optimizations early in the design phase, helping clients meet market expectations without increasing overall packaging costs.

From production scale to clean workshop management, aligning sustainability with efficient manufacturing ensures that eco-friendly packaging remains commercially viable in long-term supply chains.