Production Capacity Guarantee – Large-Scale Production

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Tea Packaging Boxes Manufacturers and OEM Tea Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

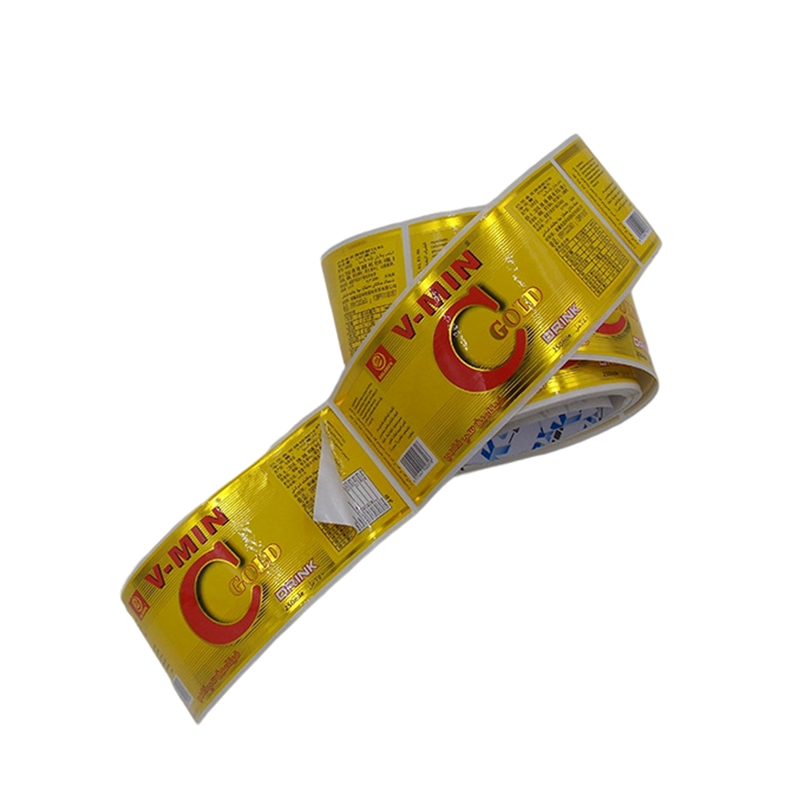

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Tea Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Tea Packaging Boxes Manufacturers

Purpose-built for hot & cold beverages—from boba milk tea to cold-brew infusions—ensuring safety, functionality, and brand consistency from store to sip.

1. Core Protection: Preserve Temperature & Integrity

Heat-Insulating: Thick, natural kraft paper provides thermal buffering—preventing burns during handling and delivery of hot drinks.

Leak-Resistant Barrier: Food-grade PE or water-based coated lining blocks seepage from lids or condensation—keeping hands, clothes, and co-packed items dry.

Short-Term Heat Retention: Reinforced walls + secure top closure slow heat loss—maintaining optimal drinking temperature for 15–25 mins.

Food-Safe & Odor-Free: Certified food-contact paper—no VOCs, PFAS, or off-flavors—to protect beverage purity and meet FDA/EU standards.

2. Delivery-Ready Functionality

Ergonomic Carry: Reinforced handles distribute weight evenly—ideal for riders (hangable on scooters) and customers (comfortable for walking/takeaway).

Modular Sizing: Single-cup, dual-slot, or 4-cup configurations with anti-slip cup holders—minimizing movement and spills during transit.

Hot & Cold Versatile: Breathable structure manages steam (hot) and wicks/contains condensation (cold)—no soggy bottoms or drips.

User-Friendly Access: Tear-notches or open-top designs allow quick cup retrieval; disposable after use—zero cleanup.

3. Brand & Sustainability Edge

Eco-Positioning: Recyclable & industrially compostable (certifiable to ASTM D6400/EN 13432)—strengthens brand credibility with eco-conscious Gen Z/Millennial consumers.

Premium Visual Appeal: Natural kraft texture + crisp CMYK/foil printing elevates perceived quality—perfect for specialty tea houses, artisanal boba brands, or wellness-focused concepts.

Scalable Cost Efficiency: Lower MOQ and unit cost vs. non-woven alternatives; customizable by weight (90g–150g), coating (matte/satin), and features (cup dividers, window cutouts)—suits startups to national chains.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

The Role of Tea Packaging Boxes in Brand Value and Product Protection

Tea packaging boxes are not just outer containers; they play a direct role in protecting tea quality, extending shelf life, and communicating brand value. Tea is highly sensitive to moisture, light, and odors, so well-structured packaging is essential to preserve aroma, flavor, and freshness throughout storage and transportation. At the same time, packaging is often the first point of contact between a tea brand and consumers, influencing purchasing decisions.

Common Types of Tea Packaging Boxes and Their Applications

Different tea products and sales channels require different packaging structures. Choosing the right box type helps balance protection, cost, and visual appeal.

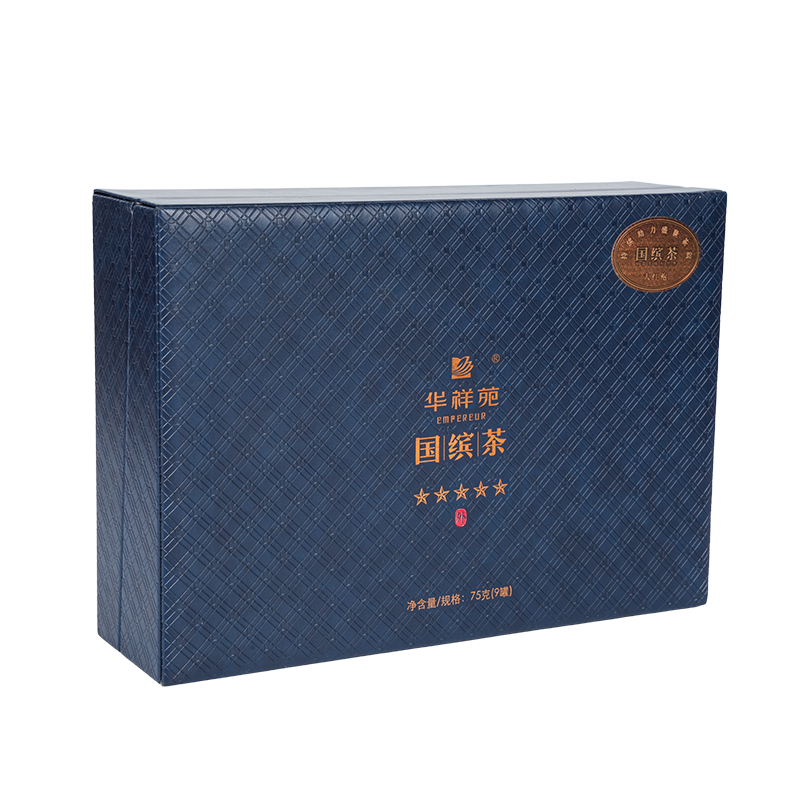

- Lid-and-base boxes (Tian Di Gai boxes): Suitable for premium loose-leaf tea and gift sets, offering strong structure and an elegant opening experience.

- Book-style boxes: Ideal for branded collections and high-end retail packaging, allowing large surface areas for storytelling and design.

- Drawer boxes: Practical for daily-use tea products, combining convenience with a refined appearance.

- Corrugated and aircraft boxes: Commonly used for shipping and e-commerce tea packaging, providing cost-effective protection during transport.

Key Materials Used in Tea Packaging Boxes

Material selection directly affects durability, sustainability, and printing quality. Tea brands should select materials based on product positioning and distribution needs.

| Material | Features | Typical Use |

| Grey board + coated paper | Strong structure, premium printing | High-end tea gift boxes |

| Corrugated paper | Lightweight, cost-effective | E-commerce and bulk shipping |

| Specialty paper | Textured, eco-friendly options | Boutique and artisan tea brands |

Customization Factors That Matter in Tea Packaging Boxes

Effective tea packaging customization focuses on functionality first, then aesthetics. Structural design must fit tea tins or inner bags precisely, while surface finishes enhance brand recognition.

- Size and internal structure designed to prevent movement and crushing.

- Printing techniques such as hot stamping, embossing, or matte lamination to improve visual quality.

- Sustainable material options to align with eco-conscious consumer expectations.

Manufacturing Capability Behind Reliable Tea Packaging Boxes

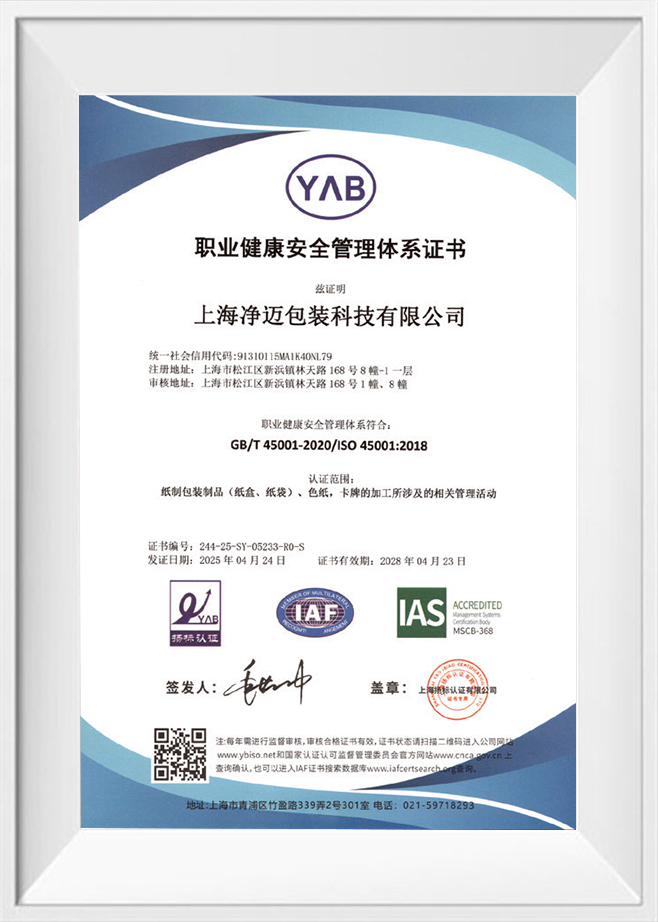

Stable quality and timely delivery depend on the manufacturer’s production capacity and process control. Shanghai Jingmai Packaging Technology Co., Ltd. operates a 13,000-square-meter production base in Songjiang District, Shanghai, with 180 employees and a newly built clean workshop. This scale allows the company to efficiently handle large-volume tea packaging box orders while maintaining consistent quality.

Equipped with advanced printing, automatic die-cutting, hot stamping, film laminating, and box-making machines, Shanghai Jingmai Packaging Technology Co., Ltd. offers complete in-house production. The factory is certified under the ISO9001 quality management system, ensuring strict quality control from material selection to final inspection.

One-Stop Solutions for Custom Tea Packaging Boxes

For tea brands, managing multiple suppliers can increase cost and risk. A one-stop packaging solution simplifies the process and improves efficiency. Shanghai Jingmai Packaging Technology Co., Ltd. provides integrated services including design support, sampling, structural confirmation, material procurement, mass production, and logistics.

By combining diverse packaging structures, advanced equipment, and experienced personnel, the company supports tea brands in developing practical, visually appealing, and market-ready tea packaging boxes without unnecessary complexity.