Production Capacity Guarantee – Large-Scale Production

Our production base is located at No. 58 Hongmudan Road, Songjiang District, Shanghai, covering a workshop area of 13,000 square meters with a grand scale. Custom Food Packaging Boxes Manufacturers and OEM Food Packaging Boxes Factory in China. We have 180 employees and a newly built clean workshop, which can simultaneously meet customers’ large-scale production needs and quality requirements.

Advanced Personnel & Equipment – High Production Quality

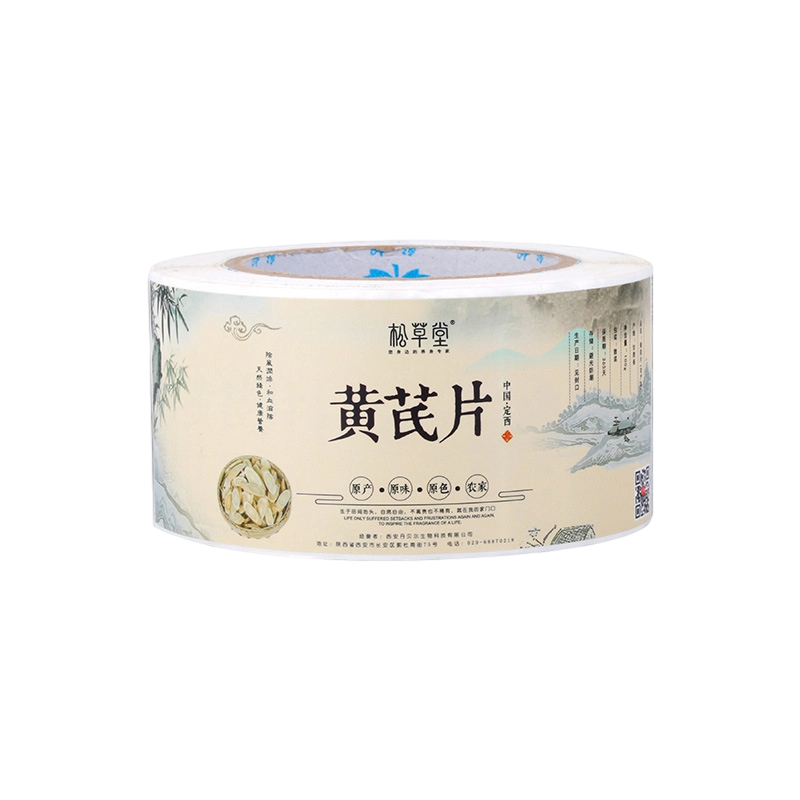

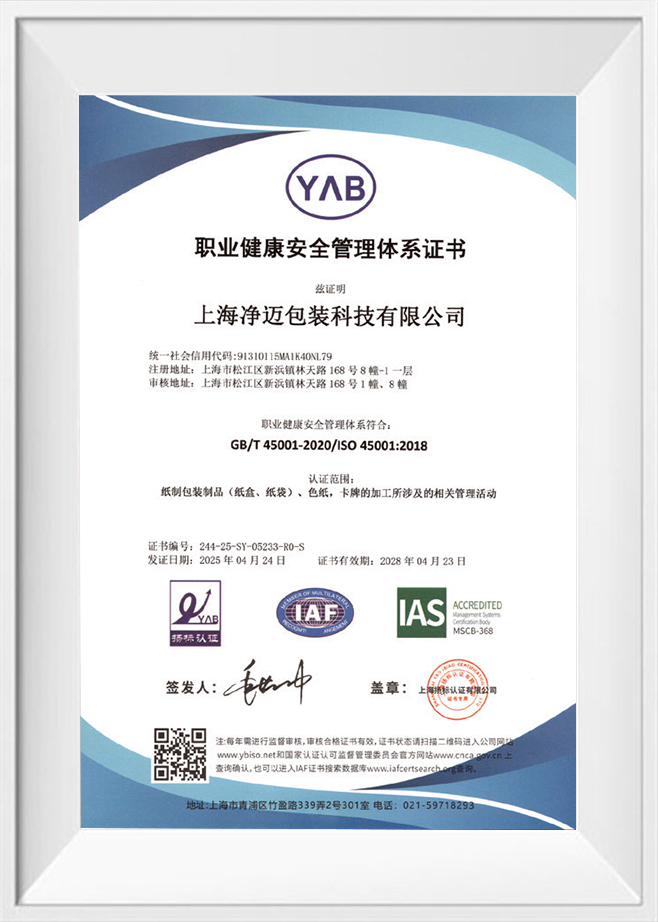

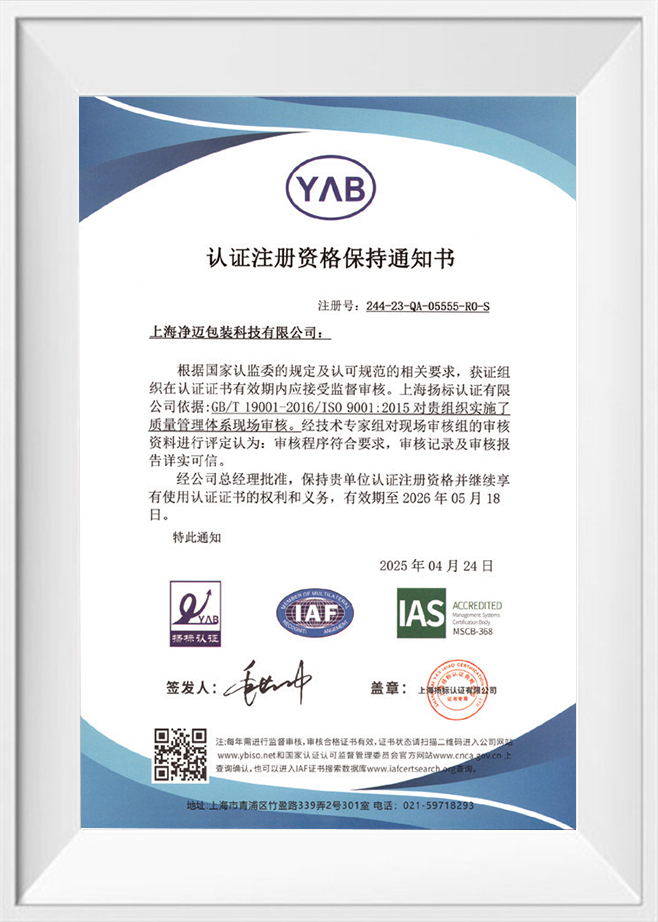

We are equipped with a complete set of advanced production equipment, including printing, automatic die-cutting, hot stamping, automatic film laminating, and automatic box-making machines. We also have comprehensive equipment for paper mounting, box gluing, and bag making. Certified by the ISO9001 international standard quality management system, we have a sound quality control system.

Rich Production Lines – Meeting Diverse Needs

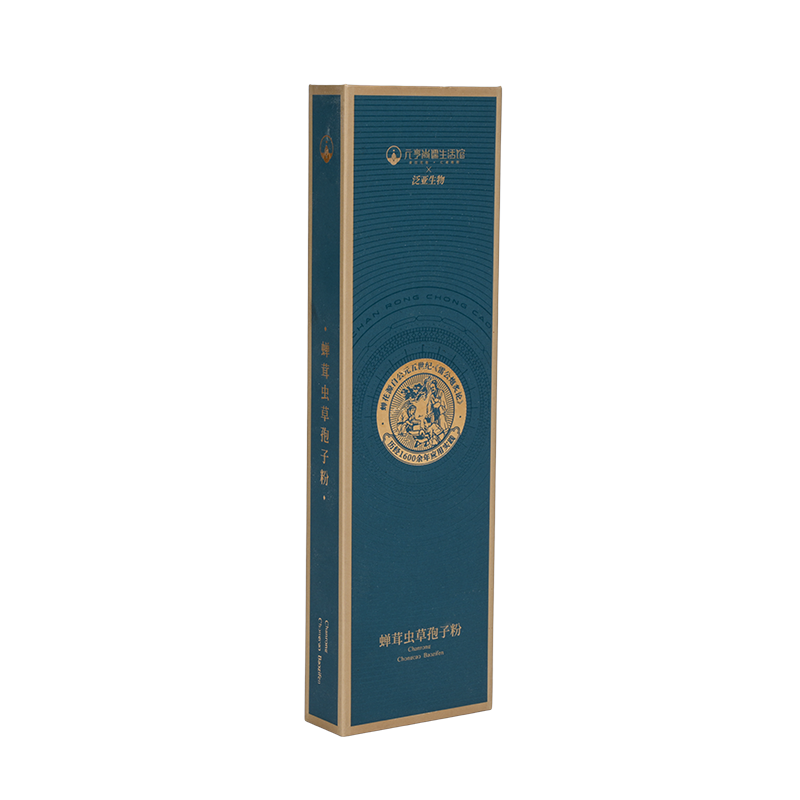

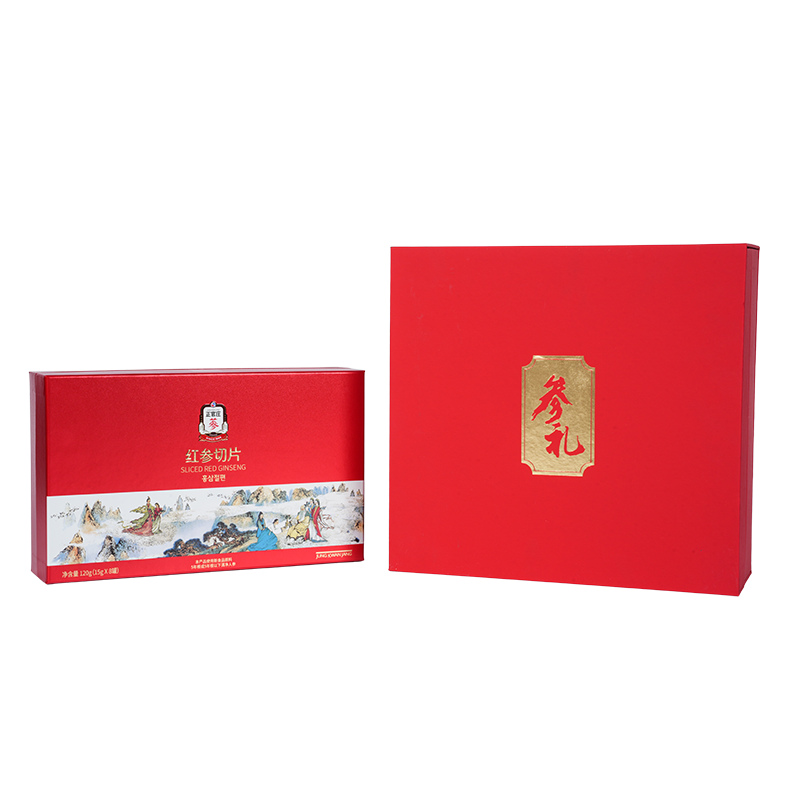

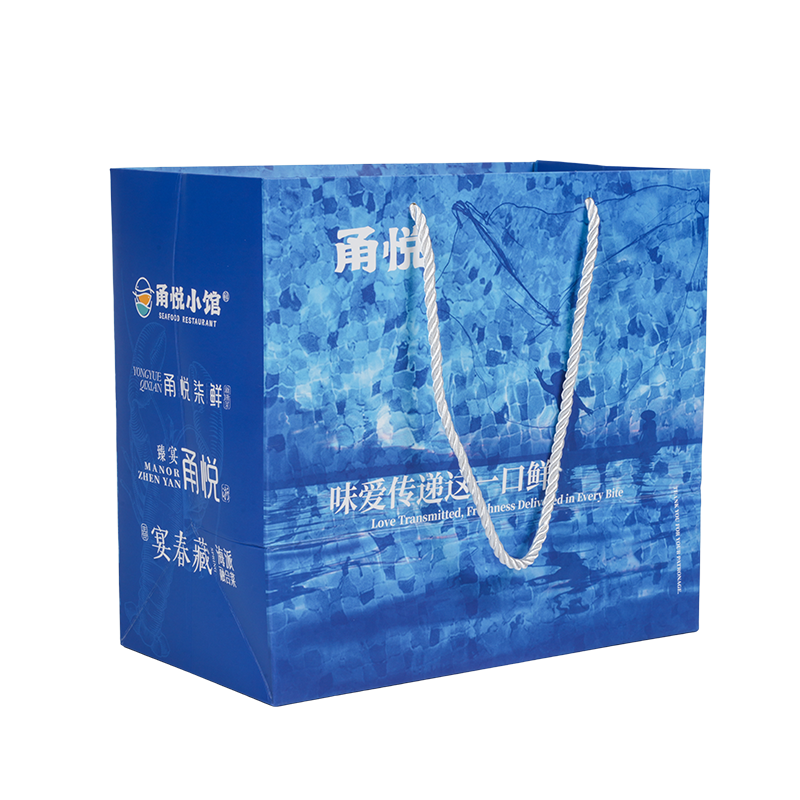

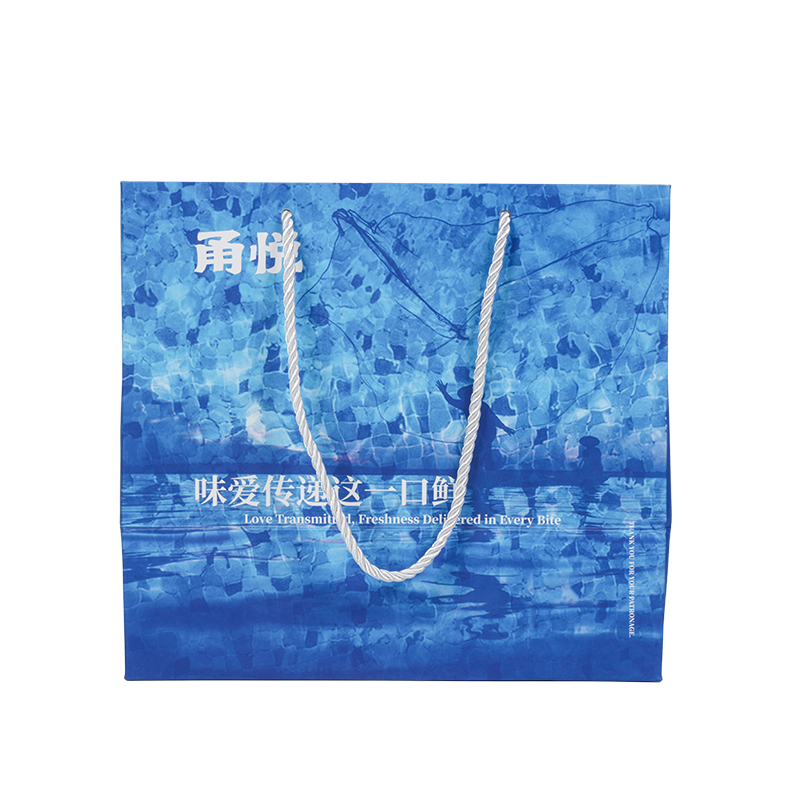

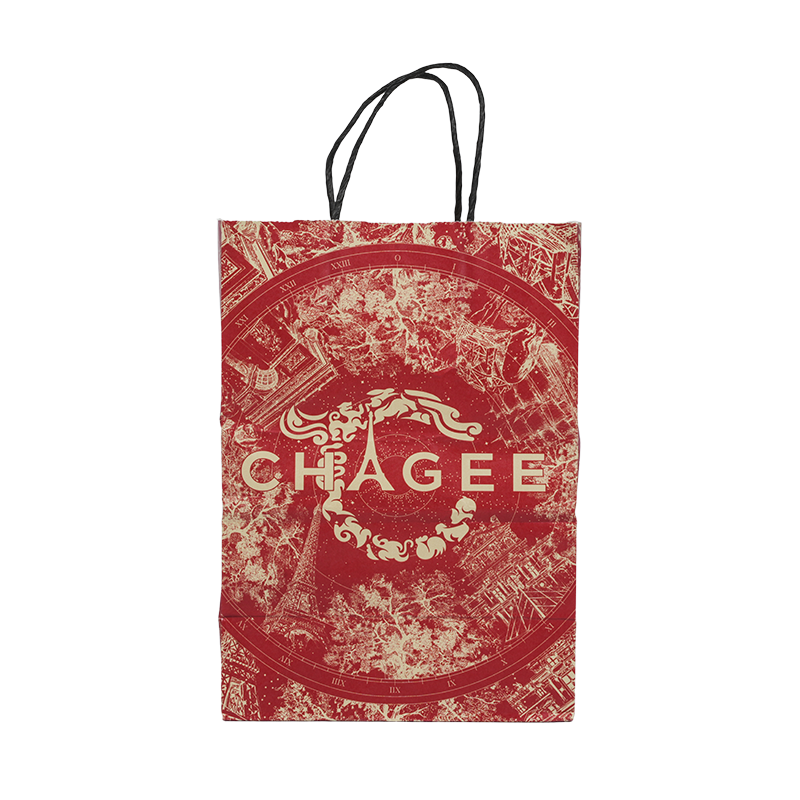

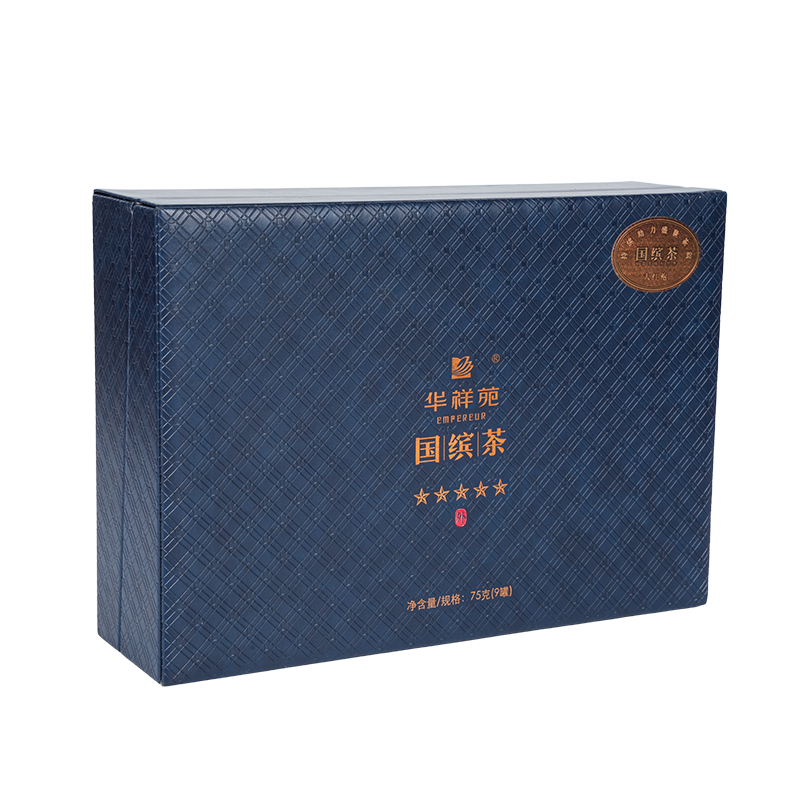

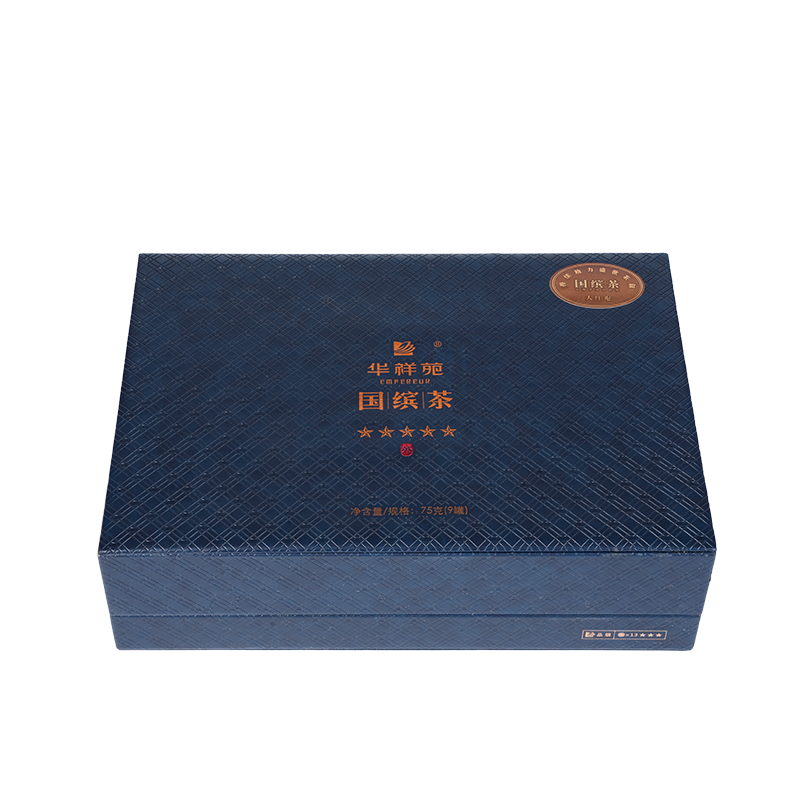

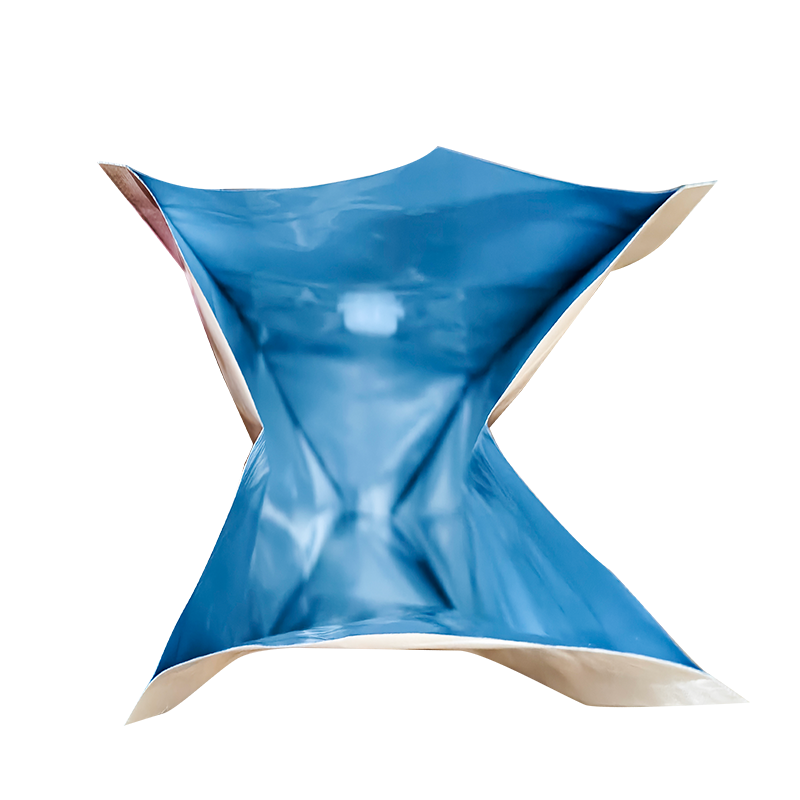

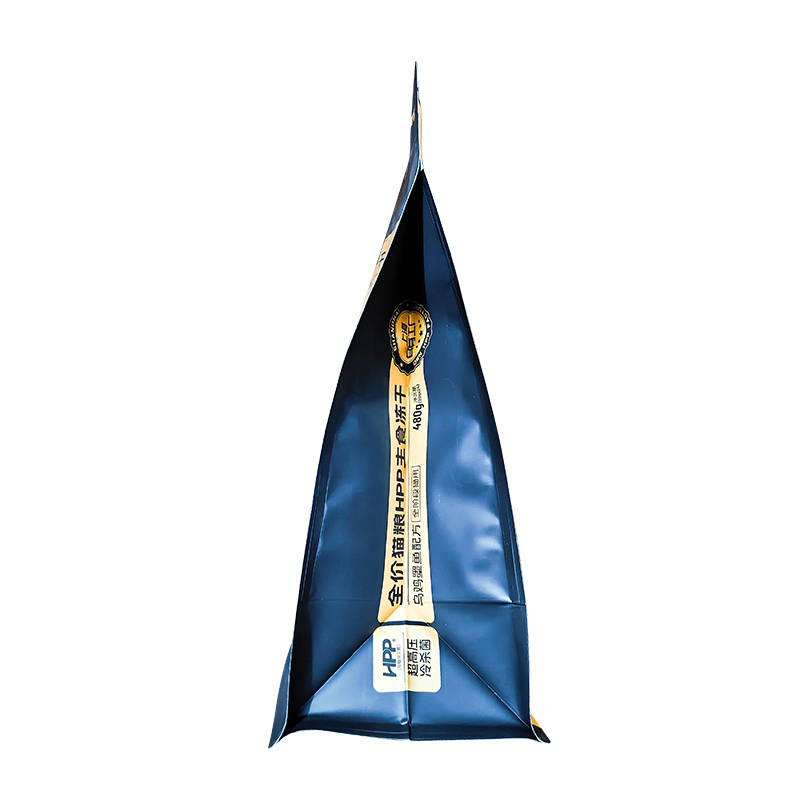

We mainly operate various packaging boxes of different materials, such as boxes (tian di gai boxes), book-style boxes, drawer boxes, aircraft boxes, corrugated boxes, paper bags, double-door boxes, Food Packaging Boxes custom, various customized special-shaped boxes, as well as various paper products, acrylic printed products, anime peripheral products, etc. We also provide a complete one-stop service from design, sampling, finalization, material selection, procurement, production to logistics.

Food Packaging Boxes Manufacturers

Food packaging is a key component in food production, storage, and sales. Its core value lies in safety protection, regulatory communication, and user experience, covering essential dimensions such as material, functionality, and classification.

Core Functions of Food Packaging

Safety Protection:

Food packaging isolates oxygen, moisture, and bacteria to prevent spoilage and contamination while extending shelf life. Common solutions include oxygen-barrier vacuum packaging and cushioned gift boxes to reduce damage during handling.

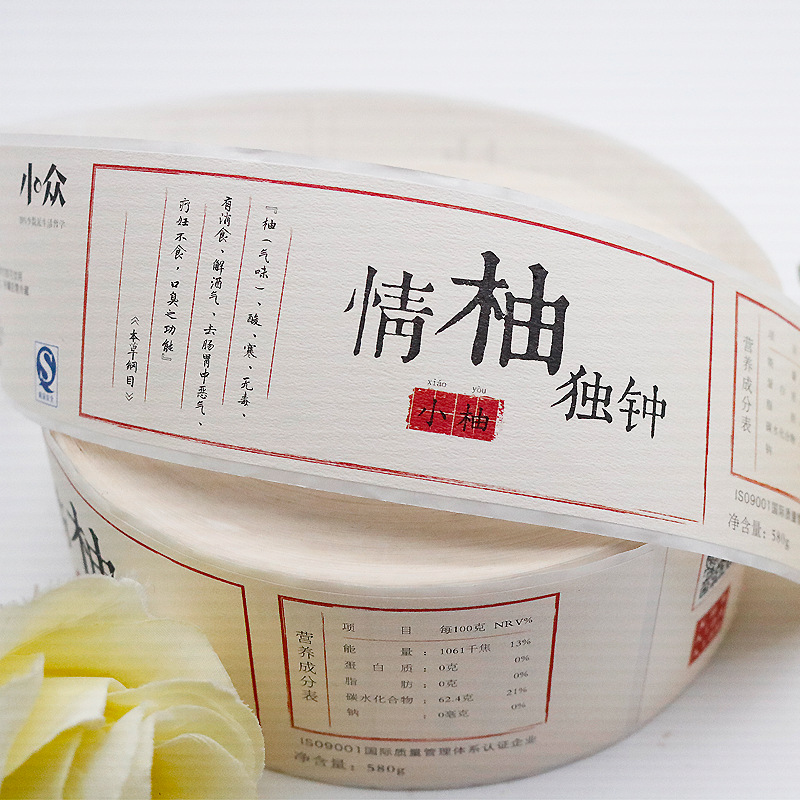

Regulatory Information Transmission:

Packaging must clearly display required information such as product name, ingredient list, production date, shelf life, and manufacturer qualifications to comply with food safety regulations.

Convenient Use:

Packaging is designed to support various usage scenarios, including storage (moisture-resistant zipper bags), transportation (rigid gift boxes with better impact resistance), and consumption (easy-tear pouches for quick opening).

Branding and Marketing:

The design and material of packaging help convey product positioning and enhance brand perception. For example, gift boxes reflect a premium feel, while white-card paper bags highlight an eco-friendly image.

-

Market Forces Driving the Food Packaging Box Industry The global Food Packaging Box market is experiencing accelerated growth due to changing consumer lifestyles, rapid urbanization, and the expansion of food delivery services. Increasing demand for convenience foods, ready-to-eat meals, and e-commerce grocery platform...

Read More -

In today's highly competitive fashion industry, a clothing brand's success depends not only on the quality of its products but also on the way it presents itself to consumers. One often-overlooked aspect of this presentation is apparel packaging. Apparel packaging boxes serve as the first physical touchpoint a consumer...

Read More -

Cosmetic products, whether they are skincare items, makeup, or hair care solutions, are highly sensitive to environmental factors such as light, air, temperature, and humidity. These factors can negatively impact the quality, effectiveness, and shelf life of products. Cosmetic packaging boxes, which are the first line ...

Read More -

Understanding the Role of Apparel Packaging in Modern Retail Apparel packaging has evolved far beyond its traditional role of protecting garments during transportation. In today’s competitive retail environment, packaging acts as a silent salesperson, shaping customer perceptions before a product is even touched. Premi...

Read More

Material Selection for Food Packaging Boxes

Choosing the right material for food packaging boxes is critical for both safety and product preservation. Food-grade paperboard, corrugated cardboard, and coated paper are widely used due to their durability, printability, and compliance with health regulations. Paperboards with moisture-resistant coatings prevent grease, oil, or liquids from leaking, maintaining the integrity of both the food and the packaging. Selecting the correct material also enhances the unboxing experience by providing a sturdy and visually appealing structure.

Additionally, different types of food require different levels of protection. For dry snacks, thin kraft paper or cardboard may suffice, while perishable or greasy foods benefit from laminated or wax-coated materials that resist moisture and maintain freshness.

- Paperboard: strong and printable, suitable for bakery products.

- Corrugated cardboard: ideal for shipping and transporting multiple food items.

- Laminated or wax-coated boards: moisture-resistant for oily or wet foods.

- Recyclable and eco-friendly materials to meet sustainability standards.

Design and Functional Considerations

Food packaging boxes must balance aesthetic appeal and functionality. Designs can include tian di gai boxes for quick assembly, drawer-style boxes for premium products, or windowed boxes to display the contents. Proper structural design ensures that boxes remain stable during storage and transportation, minimizing product damage. Reinforced edges and interlocking flaps increase durability, while compartment inserts can separate items to prevent crushing or mixing.

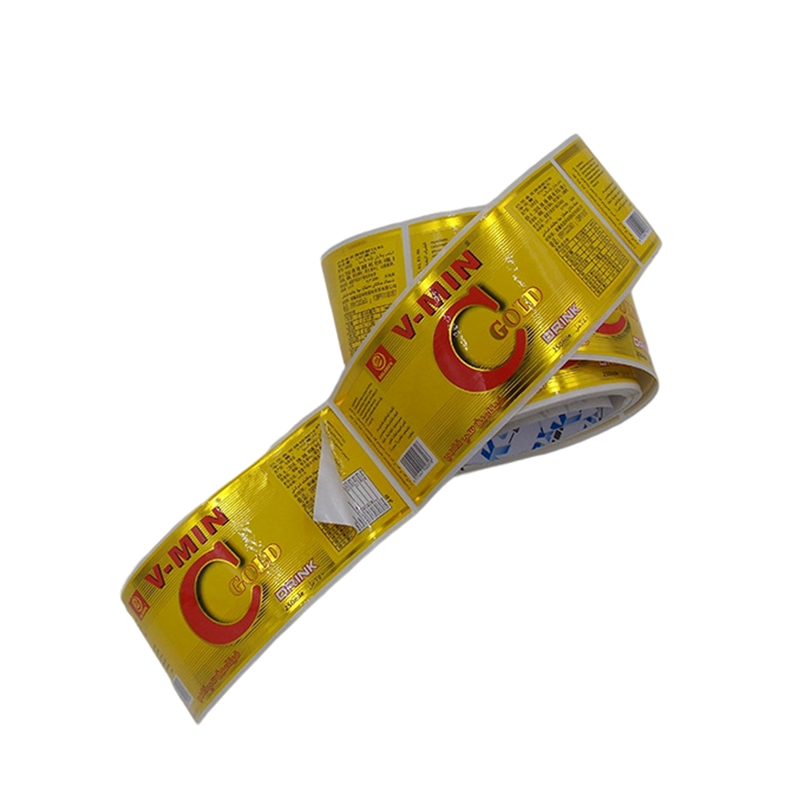

Graphic design and finishing also play a vital role. Hot stamping, embossing, and high-resolution printing can enhance brand visibility, while clear labeling communicates nutritional information and handling instructions. Food packaging designers must also consider regulatory compliance, ensuring that inks, coatings, and adhesives are non-toxic and suitable for direct contact with food.

- Windowed designs to showcase food while protecting it.

- Compartment inserts for delicate or assorted items.

- Structural reinforcements to prevent crushing during transport.

- High-quality printing and finishing for brand impact.

Production Technologies for Food Packaging Boxes

Advanced production technologies ensure precision, consistency, and safety in food packaging. Automatic die-cutting machines produce exact folds and cuts, while hot stamping and lamination enhance surface durability and visual appeal. Film laminating provides a protective layer that resists moisture and grease, extending shelf life. Box-making machines assemble the final structure efficiently, maintaining uniformity across high-volume production runs.

Quality control is essential at every stage. Paper mounting, gluing, and finishing must meet ISO9001 standards to ensure that all boxes comply with food safety regulations and perform reliably during shipping and storage.

- Die-cutting machines for precise shapes and folds.

- Hot stamping and lamination for durability and aesthetics.

- Film lamination for moisture and grease resistance.

- ISO9001 quality control for consistent production standards.

Custom Solutions and One-stop Services

One-stop packaging services allow businesses to manage design, prototyping, material selection, production, and logistics in a single workflow. Custom solutions can accommodate unique product shapes, premium finishes, or specific branding requirements. For example, aircraft boxes or special-shaped boxes provide structural support for delicate foods, while drawer boxes create a premium unboxing experience for luxury confectionery or chocolates.

Working with a provider capable of integrating design and production reduces lead times, ensures quality consistency, and allows for rapid adjustments to accommodate seasonal or limited-edition products.

- Customized sizes and shapes for unique product lines.

- Integrated design and production for rapid prototyping.

- Coordinated finishes and branding across multiple box types.

- Comprehensive service from design to delivery for efficiency.

Safety and Regulatory Compliance

Food packaging boxes must comply with strict safety and hygiene standards. Materials, inks, adhesives, and coatings should be certified for food contact. Ensuring compliance reduces the risk of contamination and protects consumers. Clear labeling of nutritional information, storage instructions, and allergen warnings is also a critical aspect of regulatory adherence.

Regular inspections and testing during production help identify potential safety issues, such as material contamination or defective printing. Maintaining ISO9001 certification further guarantees that production processes are standardized and controlled, minimizing the risk of quality lapses.

- Use food-grade certified materials, inks, and adhesives.

- Ensure clear and accurate labeling of ingredients and handling instructions.

- Regular inspections to maintain hygiene and safety standards.

- ISO9001 certification ensures consistent quality control processes.

Comparing Box Types for Different Food Applications

Selecting the right box type depends on product characteristics, weight, and presentation goals. A comparative overview helps identify optimal solutions:

| Box Type | Ideal Application | Key Features |

|---|---|---|

| Tian Di Gai Box | Bakery items, dry snacks | Quick assembly, durable, printable surface |

| Drawer Box | Premium confectionery, chocolates | Sliding mechanism, reusable, premium feel |

| Aircraft Box | Fragile or high-value foods | Reinforced structure, protective inserts |

Choosing the appropriate packaging box ensures food safety, maintains product integrity, and enhances brand presentation.